Product Description

Product Description

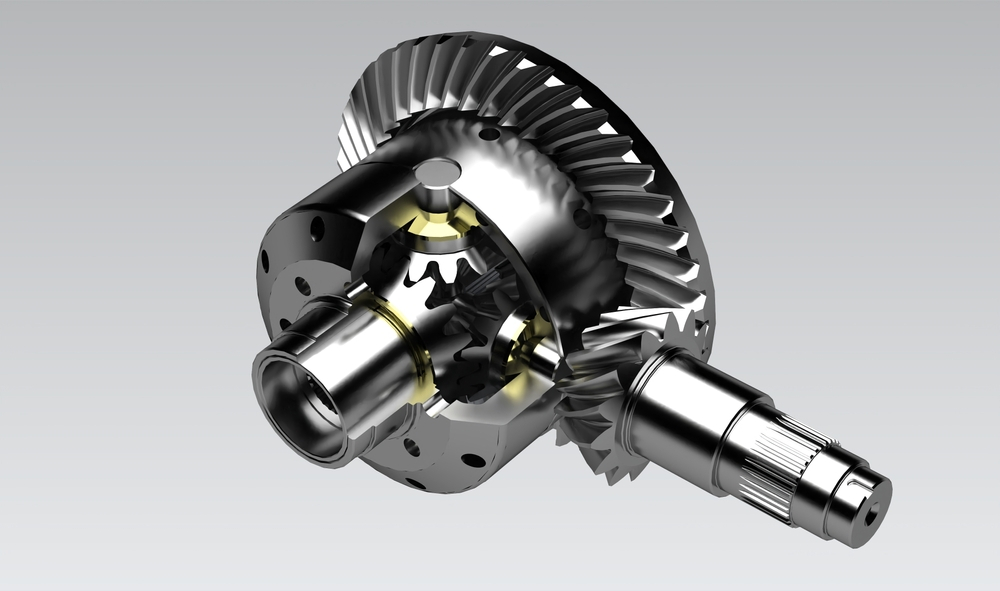

TZCS-400-A Differential Wheel with Suspension

This model is 1 of the AGV accessories.It can provide the power to AGV, is the most important load parts. The differential wheel is not equipped with a steering motor, which means that the driving wheel itself cannot rotate, but the steering is realized by the speed difference between the inner and outer driving wheels.

Product Parameters

Dimensions

Product Advantages

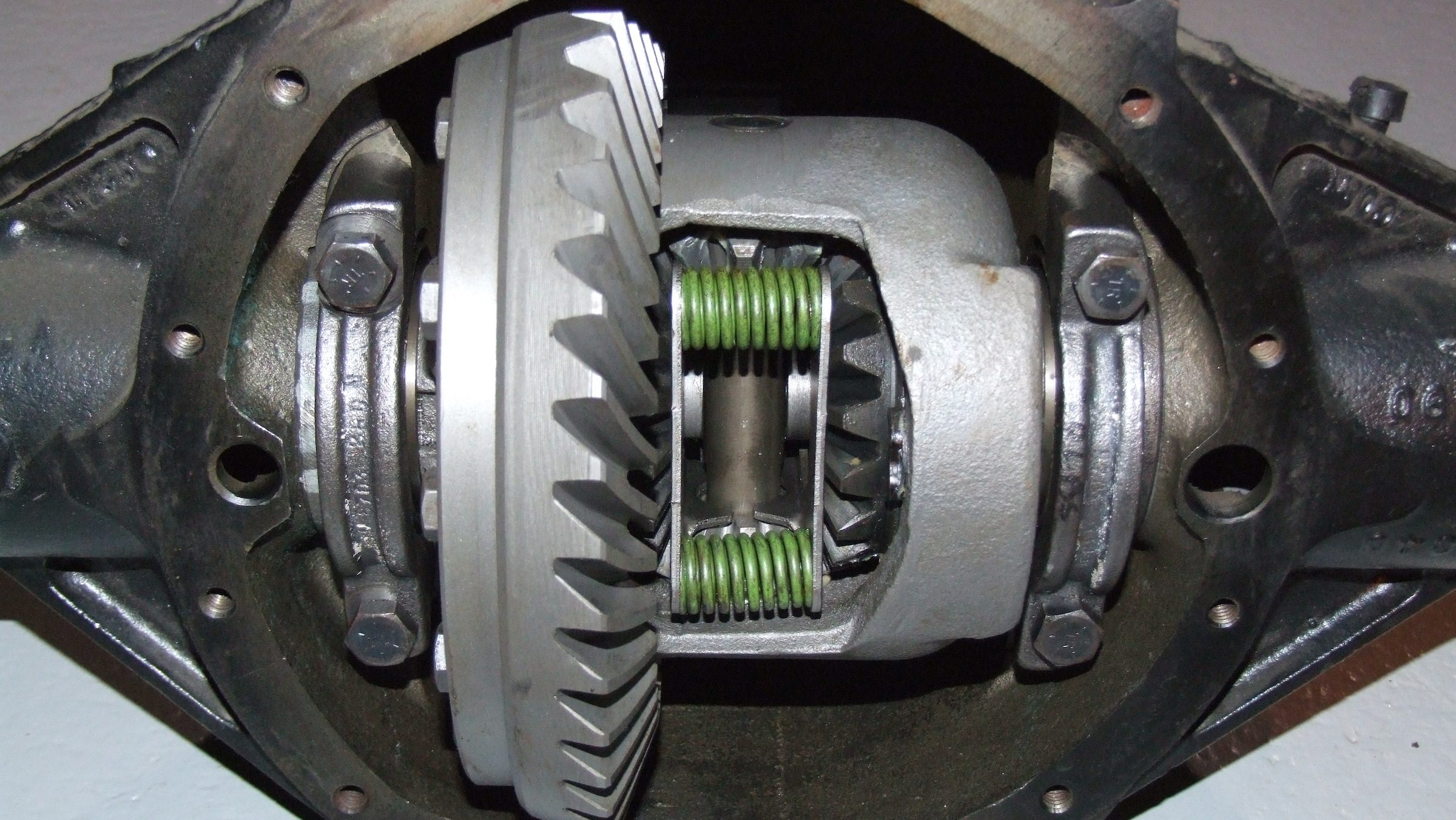

Detailed Photos

Company Profile

ZHangZhoug CHINAMFG Technology Co., Ltd founded 2015, in ZHangZhouG designs, manufactures and sells agv, driving wheel assembly, DC/AC motors, encoder, reducer, controller, caster wheel, gear, Pu wheel, motor in wheel units and all over the world.

TZBOT continues to bring excellent products, technological innovation and ease of customizing to the automated equipment.

The factory, is 1000 sq. feet, and employs 50 people. The company is certified to ISO9001:2015.

The core to TZBOT’s growth is the constant dedication to the pursuit of full customer satisfaction. They have a strong presence in domestic and international markets, as well as, great production flexibility. CHINAMFG has come to be recognized as 1 of the biggest suppliers of electric drive.

Continued investment in the most modern machinery has further increased and developed the quality and flexibility of each product.

Today, CHINAMFG can quickly design and produce engines and special parts request from customers.

TZBOT’s product are used in a myriad of application, including but not limited to: Forklifts, AGV, Aerial Platforms, Airport Machines, Agricultural Machines, Hydraulic Applications, Floor Scrubbers, Sweepers, Wind Energy, Marine, and in the field of Medical Devices.

All prototypes are tested for extended periods of time to verify the quality and the duration will work perfectly before sending production parts to customers. Due diligence is paramount to the satisfaction of our customers.

Certifications

FAQ

Q: Payment

A: Our payment is T/T, Paypal, West Union, Trade Assurance(Ali pay or E-check), L/C, and D/P.

Q: After-sale service

A: For assured quality all products, we check all products’ quantity twice. The first time is end of production, the second time is before packing into cartons. If any negligence or accident about our goods, after received goods within 10 days, please don’t worry to contact us at any time. We will reply you in 24 hours and let you choose solutions to meet your satisfactory.

Q: Our advantage

A: Free cameraman special for you: Supply high quality photos for you after ordered. Save tax: We can make C/O, Form E, Form-F and so on. They can help you save 10~30$ custom tax. Reduce freight rate: We compress beds, integration space and talk with express. Just for saving freight rate for customer. Usually, by the way, it can save about 20%~35% shipping cost. And we are trying to improve all the time. We have a professional technical team: We can provide a full range of pre-sale consulting and after-sale technical guidance.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Skid-Resistance, Wear-Resistant |

| Application: | Packaging Machinery |

| Surface Treatment: | Polishing |

| Material: | Aluminum |

| Load Capacity: | 600kg |

| Customization: |

Available

| Customized Request |

|---|

How do differential gears handle varying speeds in a vehicle’s wheels?

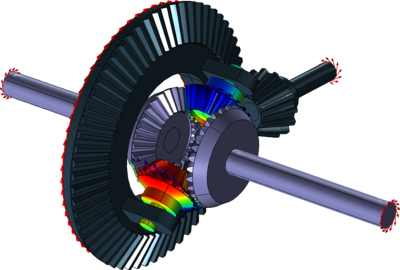

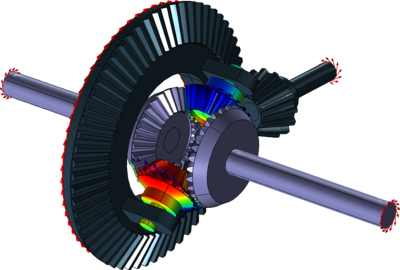

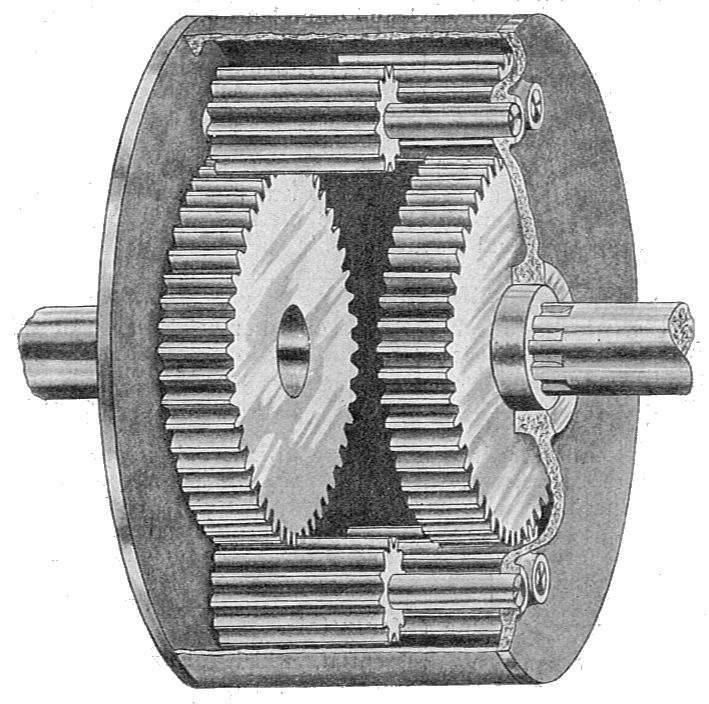

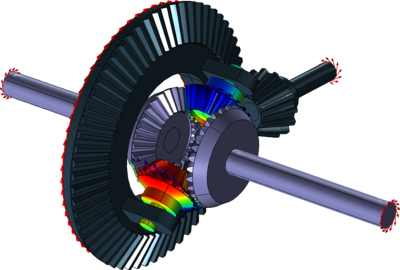

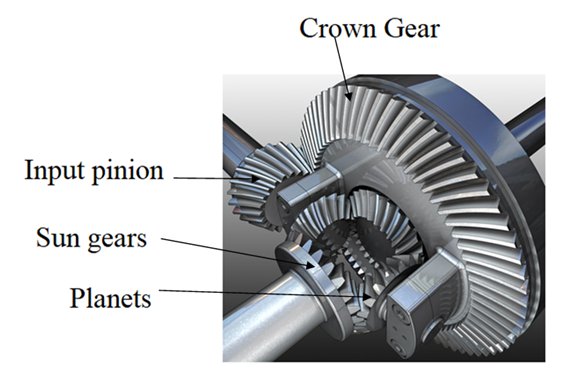

A differential gear system is designed to handle varying speeds in a vehicle’s wheels, allowing them to rotate at different rates while maintaining torque distribution. Here’s a detailed explanation of how differential gears achieve this:

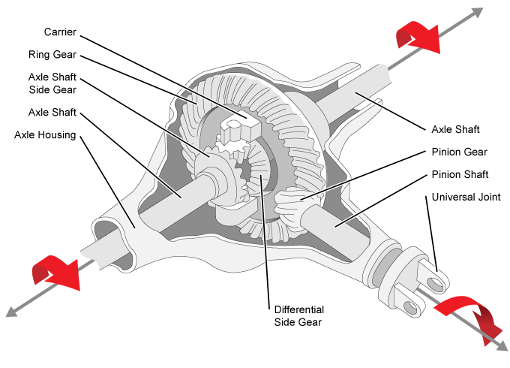

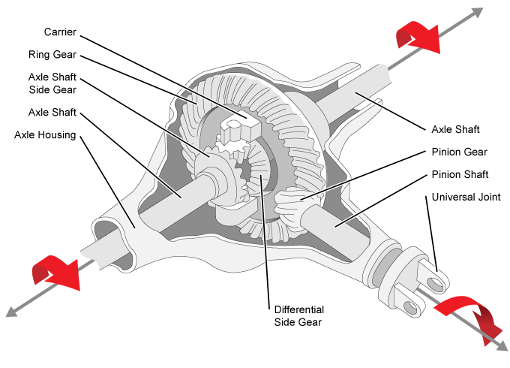

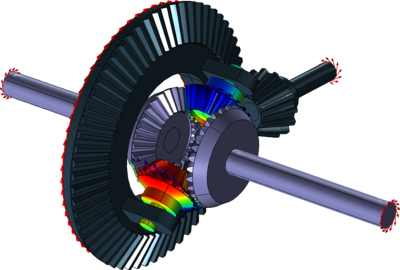

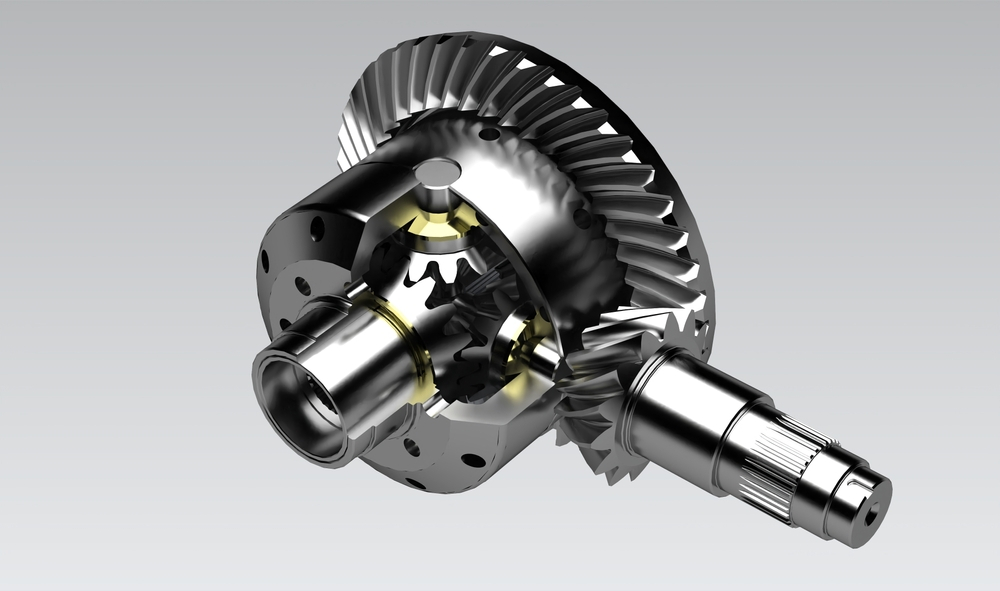

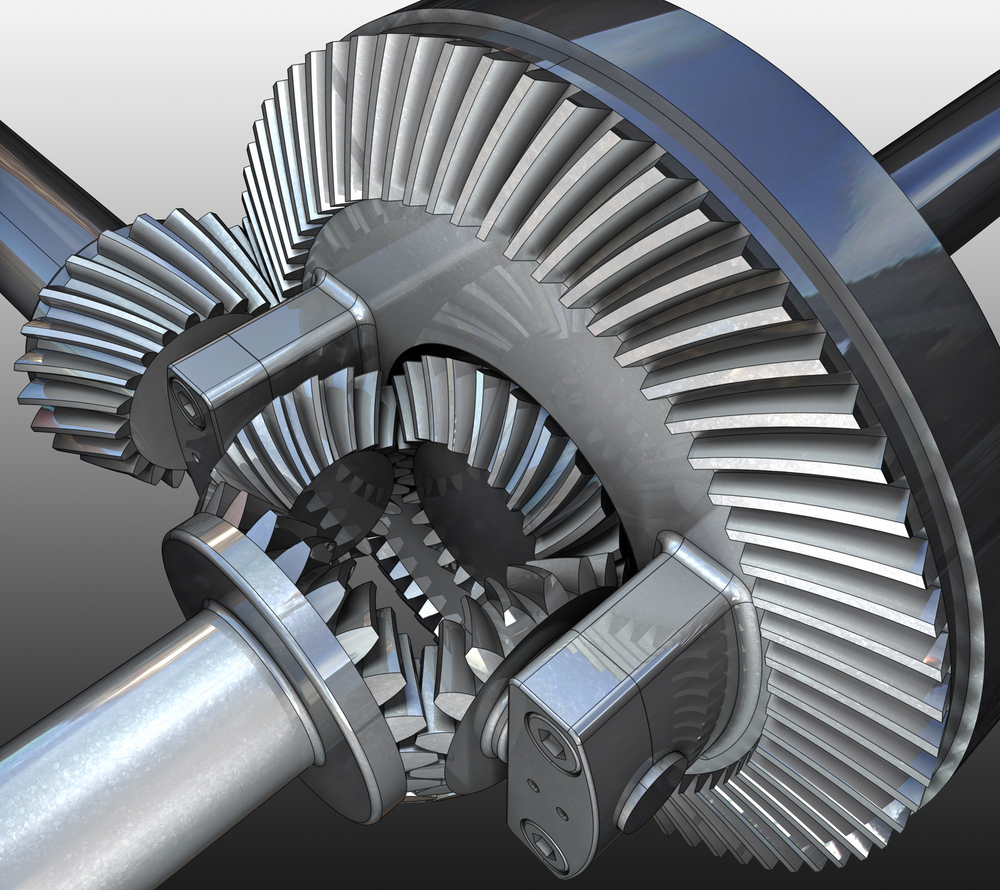

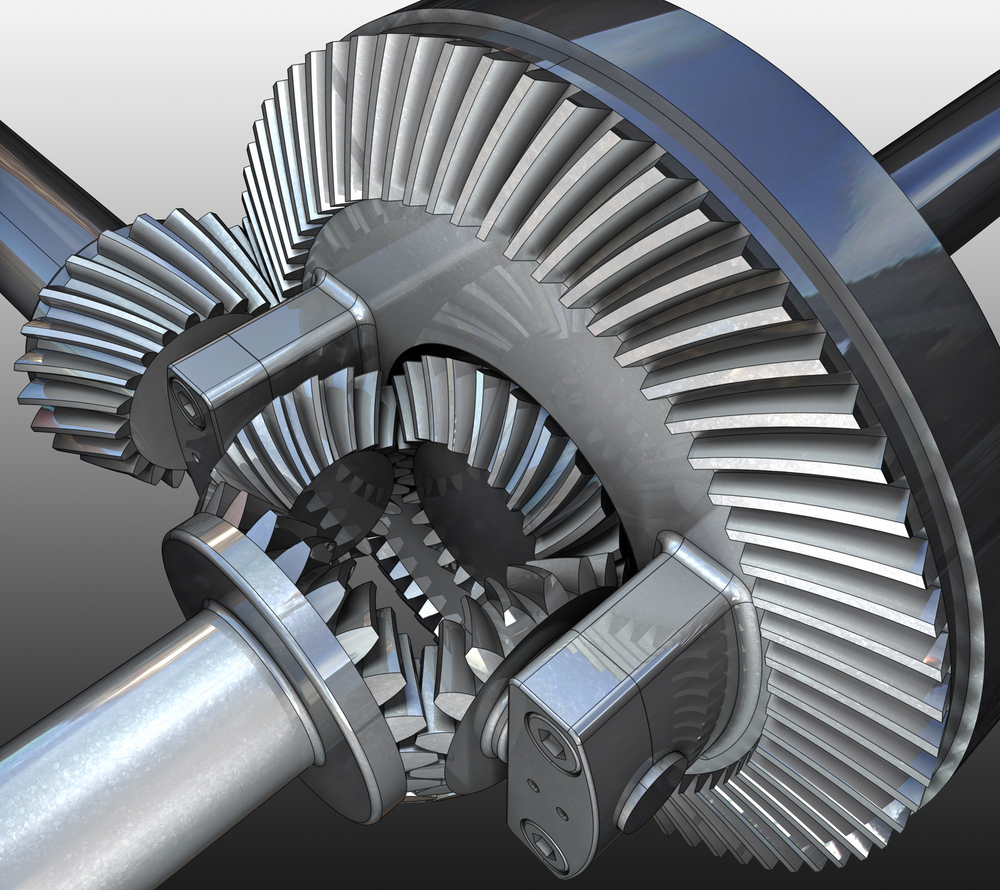

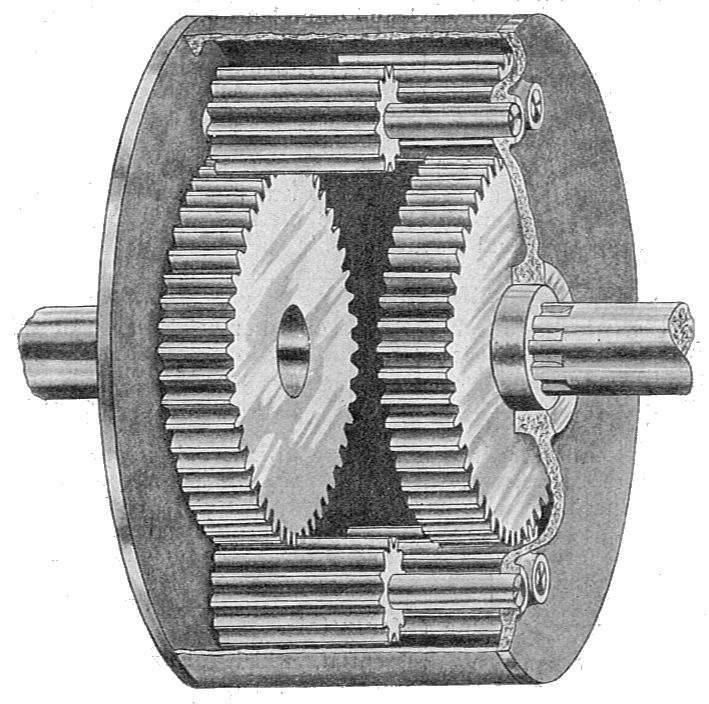

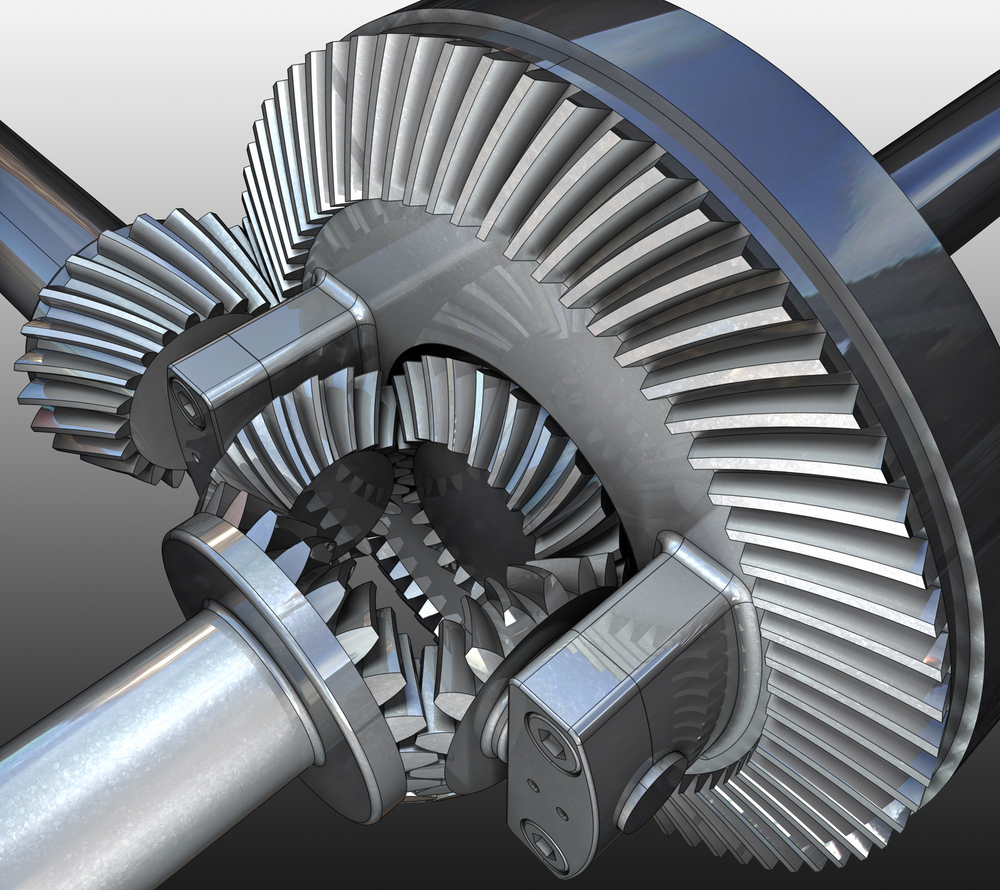

1. Differential Assembly:

The differential assembly consists of several gears, including the ring and pinion gears, side gears, and spider gears. These components work together to accommodate varying speeds between the wheels.

2. Power Input:

The power is delivered to the differential gears through the driveshaft or transmission. The ring gear receives this power from the driveshaft, while the pinion gear is connected to the ring gear and transfers the rotational force to the differential assembly.

3. Speed Differences:

When a vehicle is moving in a straight line, the wheels ideally rotate at the same speed. However, during turns or when encountering different traction conditions, the wheels need to rotate at varying speeds. This is because the wheel on the outside of a turn covers a greater distance than the inside wheel, resulting in a speed differential.

4. Spider Gears:

The differential gears utilize spider gears, which are small gears located between the side gears. Spider gears allow the side gears to rotate independently of each other, accommodating the speed differences between the wheels.

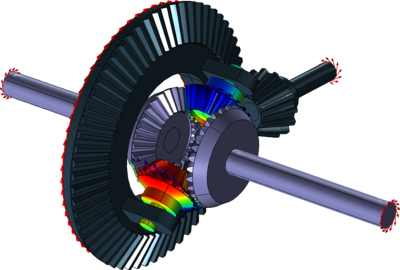

5. Torque Distribution:

As the spider gears allow the side gears to rotate independently, torque is distributed between the wheels based on their speed differences. The wheel with less resistance or greater traction receives more torque, while the wheel with more resistance or lower traction receives less torque.

6. Smooth Cornering:

During turns, the inside wheel needs to rotate at a slower speed than the outside wheel. The differential gears allow this speed differentiation, enabling smooth cornering without wheel hop or tire scrubbing. By distributing torque appropriately, the differential gears ensure that both wheels receive sufficient power for optimal traction and control.

7. Limited-Slip and Locking Differentials:

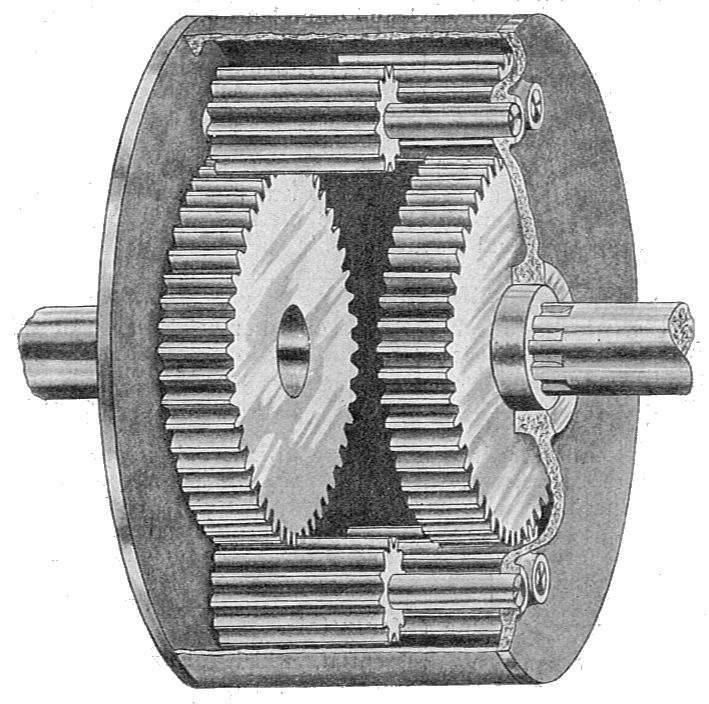

In certain differential systems, such as limited-slip differentials or locking differentials, additional mechanisms are employed to further regulate speed differences and torque distribution. Limited-slip differentials use clutch packs or friction plates to provide a predetermined amount of resistance, allowing some differentiation between the wheels while still transferring power. Locking differentials lock the side gears together, ensuring equal torque distribution to both wheels, regardless of traction conditions.

8. Differential Types:

There are different types of differentials, including open differentials, limited-slip differentials, electronic differentials, torque vectoring differentials, and more. Each type utilizes specific technologies and mechanisms to handle varying speeds and torque distribution based on the vehicle’s requirements and driving conditions.

In summary, differential gears handle varying speeds in a vehicle’s wheels by utilizing a system of gears, including spider gears, side gears, ring and pinion gears. The speed differences between the wheels are accommodated by allowing independent rotation of the side gears through the spider gears. Torque distribution is adjusted to ensure optimal traction and control during turns and varying traction conditions. Additional mechanisms, such as limited-slip or locking differentials, can further regulate speed differences and torque distribution for enhanced performance and stability.

Can differential gears be upgraded or customized for specific applications?

Yes, differential gears can be upgraded or customized for specific applications to enhance performance, traction, and handling. Here’s a detailed explanation of how differential gears can be upgraded or customized:

- Gear Ratio Changes: One way to customize differential gears is by changing the gear ratios. Different gear ratios can alter the torque distribution between the wheels, optimizing it for specific applications. For example, shorter gear ratios can improve acceleration and low-end torque, while taller gear ratios can enhance fuel efficiency and top speed. Gear ratio changes are commonly performed in performance vehicles, off-road vehicles, and racing applications to suit specific driving requirements.

- Limited-Slip Differentials (LSD): Upgrading to limited-slip differentials can significantly improve traction and handling. LSDs distribute torque between the wheels more evenly compared to open differentials, reducing wheel spin and maximizing grip. LSDs are particularly beneficial in high-performance vehicles, off-road vehicles, and applications where maintaining traction is crucial, such as racing or challenging driving conditions. LSDs can be retrofitted or factory-installed depending on the vehicle and its specific requirements.

- Electronic Differential Controls: Some vehicles feature electronic controls for the differential system. These controls allow customization of the differential’s behavior based on driving conditions and driver preferences. Through electronic controls, differential characteristics such as torque distribution, responsiveness, and traction management can be adjusted. This customization helps optimize performance, stability, and traction in various driving scenarios.

- Aftermarket Upgrades: The aftermarket industry offers various differential upgrade options. These include performance differentials, heavy-duty differentials, and specialized differentials designed for specific applications. These aftermarket upgrades can provide improved durability, enhanced traction, and higher torque capacity compared to stock differentials. They are commonly chosen by enthusiasts, off-road enthusiasts, and individuals seeking to enhance the capabilities of their vehicles for specific purposes.

- Custom Differential Designs: In certain cases, custom differential designs can be developed to meet specific application requirements. For example, in motorsports, differential designs can be tailored to optimize performance, handling, and traction for the specific demands of the racing discipline. Custom differentials may involve unique gear arrangements, specialized materials, and advanced features to deliver superior performance in targeted applications.

In summary, differential gears can be upgraded or customized to suit specific applications. Upgrades may include gear ratio changes, installation of limited-slip differentials, utilization of electronic differential controls, aftermarket differential options, or even custom differential designs. These modifications and customizations allow for improved performance, traction, and handling, catering to the specific needs and preferences of different vehicles and driving scenarios.

How does a limited-slip differential differ from an open differential?

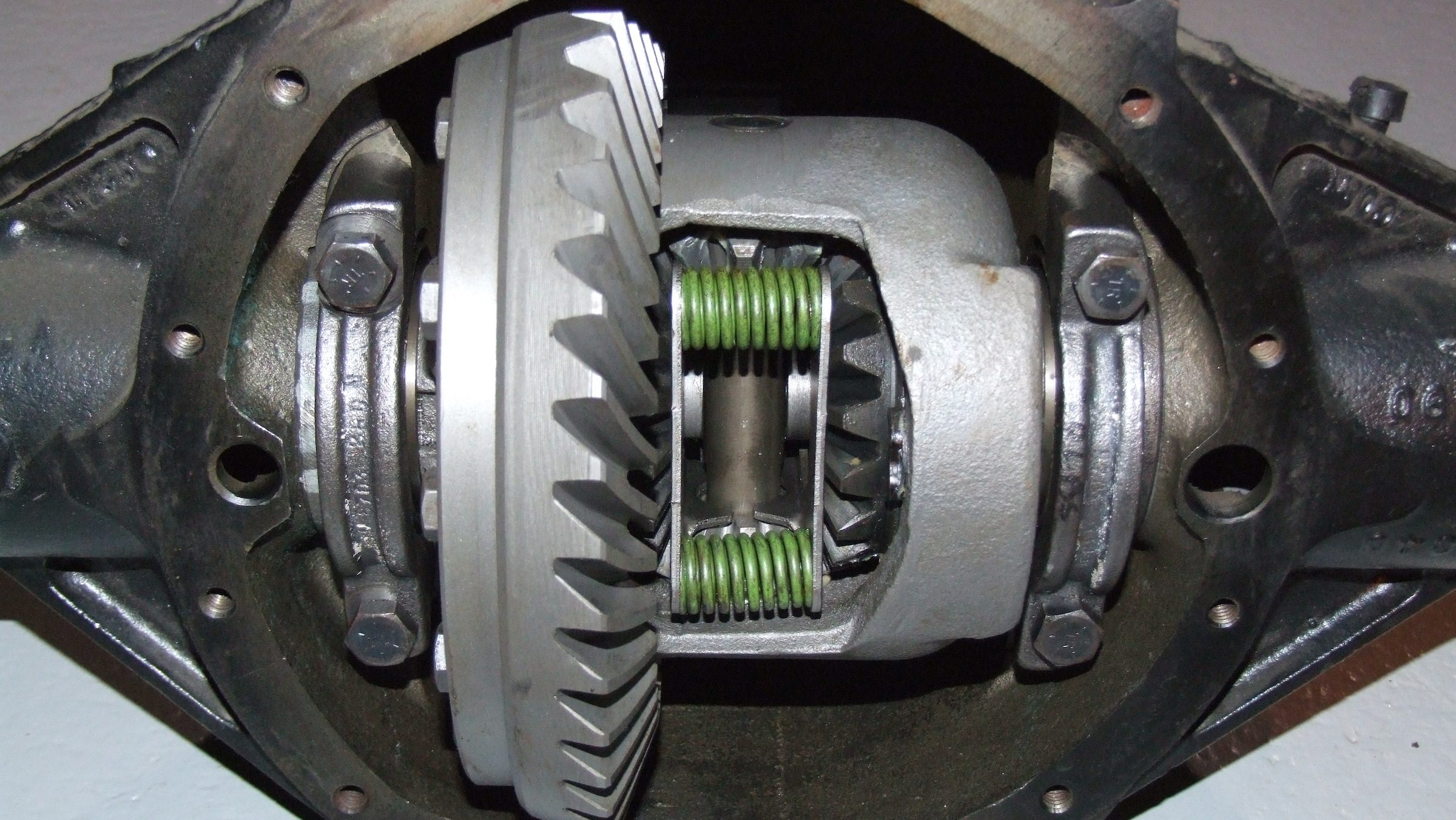

A limited-slip differential (LSD) differs from an open differential in several key ways. Here’s a detailed explanation:

1. Torque Distribution:

In an open differential, torque is distributed equally between the two wheels. When both wheels have good traction, this distribution works well. However, if one wheel loses traction, the open differential will send more power to that wheel, causing it to spin while the other wheel receives minimal power. This can result in reduced traction and compromised performance.

In contrast, a limited-slip differential actively biases torque distribution. It uses various mechanisms, such as clutch packs, viscous fluids, or gear arrangements, to transfer more torque to the wheel with better traction. This torque biasing helps improve traction and power delivery, especially in situations where one wheel has reduced traction. By providing a more balanced torque distribution, a limited-slip differential enhances overall performance and stability.

2. Traction Improvement:

One of the primary advantages of a limited-slip differential is its ability to improve traction compared to an open differential. When one wheel encounters reduced traction, such as on slippery surfaces or during cornering, the limited-slip differential transfers more torque to the wheel with better traction. This helps maximize the vehicle’s ability to maintain forward motion and improves overall stability by minimizing wheel slip. In contrast, an open differential may distribute power to the wheel with the least resistance, resulting in reduced traction and compromised handling.

3. Drivability:

In terms of drivability, open differentials are generally smoother and more predictable. They allow the wheels to rotate at different speeds during turns, facilitating smooth operation and minimizing binding or tire scrubbing. Open differentials are also less expensive to manufacture, making them a common choice for everyday vehicles.

On the other hand, limited-slip differentials offer improved drivability compared to open differentials, especially in situations with varying traction conditions. Limited-slip differentials strike a balance between improved traction and maintaining drivability for everyday use. They can provide better control and stability during acceleration, cornering, and challenging road conditions.

4. Performance and Handling:

Limited-slip differentials are often favored in performance-oriented vehicles or applications that require enhanced handling characteristics. The ability to transfer torque to the wheel with better traction helps optimize power delivery, reduce wheel slip, and improve overall performance. Limited-slip differentials can enhance cornering ability, stability, and agility, allowing drivers to navigate curves and corners with more confidence and control.

In contrast, open differentials may be more prone to wheel slip, particularly in high-performance or demanding driving situations. This can result in compromised performance and reduced stability.

In summary, a limited-slip differential differs from an open differential in terms of torque distribution, traction improvement, drivability, and performance. By actively biasing torque distribution and improving traction, a limited-slip differential offers better performance and handling characteristics, especially in challenging driving conditions.

editor by Dream 2024-05-09

China best American Standard ANSI 60 Sprocket Differential Drive CZPT worm gearbox

Product Description

| Steel Grade | 4140,4130,A1050,F11,5140,304L,316L,321,P11,F22,4340 |

| 1.2344, 17CrNiMo6, 20MnMo, S355NL | |

| 18CrNiMo7-6 | |

| 42CrMo, 40CrNiMo |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Gravity Casting |

| Application: | Agricultural Machinery Parts |

| Material: | Steel |

| Heat Treatment: | Tempering |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide examples of vehicles that use differential gears?

Differential gears are utilized in various types of vehicles to enable smooth and efficient power distribution to the wheels. Here are some examples of vehicles that use differential gears:

1. Passenger Cars:

Most passenger cars, including sedans, hatchbacks, and SUVs, are equipped with differential gears. These gears are typically found in the rear axle of rear-wheel-drive vehicles or in both the front and rear axles of all-wheel-drive vehicles. Differential gears allow the wheels to rotate at different speeds while maintaining power transfer, ensuring smooth cornering and traction on different road surfaces.

2. Trucks and Pickup Trucks:

Trucks and pickup trucks commonly employ differential gears to enhance their performance, especially for towing, hauling, and off-road applications. Rear-wheel-drive trucks utilize differential gears in the rear axle, while many modern trucks also feature all-wheel-drive or four-wheel-drive systems with differential gears in both the front and rear axles. These differential gears enable improved traction, power distribution, and maneuverability in various driving conditions.

3. SUVs and Crossovers:

Sport utility vehicles (SUVs) and crossovers often incorporate differential gears to provide enhanced off-road capability and all-weather performance. Many SUVs are equipped with all-wheel-drive or four-wheel-drive systems that utilize differential gears in the front and rear axles. These gears allow power transfer between the wheels and enable optimal traction on different terrains, making SUVs well-suited for off-road adventures and challenging driving conditions.

4. Sports Cars and Performance Vehicles:

Sports cars and high-performance vehicles often employ advanced differential systems for improved handling, stability, and performance. Examples include limited-slip differentials, electronic differentials, or torque vectoring differentials. These systems use differential gears in combination with advanced technologies to distribute torque to the wheels based on driving conditions, enhancing traction, cornering ability, and overall vehicle dynamics.

5. Off-Road Vehicles and SUVs:

Differential gears are essential components in off-road vehicles designed for rugged terrains and extreme driving conditions. Vehicles such as dedicated off-road SUVs, trucks, and specialized off-road vehicles like Jeeps and Land Rovers utilize differential gears, including locking differentials, to maximize traction and improve off-road performance. These gears allow for better wheel articulation, independent wheel movement, and power distribution to overcome obstacles and maintain traction on challenging off-road trails.

6. Commercial and Heavy-Duty Vehicles:

Commercial trucks, buses, and heavy-duty vehicles utilize differential gears to handle the demands of heavy loads and challenging driving conditions. Differential gears in these vehicles help distribute torque to the drive wheels efficiently, ensuring better traction, stability, and power transfer. They are critical for the performance and safety of large commercial vehicles that operate under varying load and road conditions.

7. Racing Cars:

In racing, differential gears play a vital role in enhancing performance and handling characteristics. High-performance racing cars, including Formula 1 cars, rally cars, and sports prototypes, utilize advanced differential systems that allow precise control of power distribution to optimize acceleration, cornering, and stability during high-speed maneuvers.

In summary, differential gears are utilized in a wide range of vehicles, including passenger cars, trucks, SUVs, sports cars, off-road vehicles, commercial vehicles, and racing cars. These gears are integral to achieving optimal power distribution, traction, and maneuverability in various driving conditions and applications.

Can differential gears be used in heavy-duty trucks and commercial vehicles?

Yes, differential gears can be used in heavy-duty trucks and commercial vehicles. In fact, they are an essential component of the drivetrain in most vehicles, including those designed for heavy-duty applications. Here’s a detailed explanation:

Differential gears are crucial for effective power distribution and maneuverability, especially in vehicles with multiple axles or large payloads. Here are some reasons why differential gears are used in heavy-duty trucks and commercial vehicles:

- Torque Distribution: Differential gears enable the proper distribution of torque to the wheels. In heavy-duty trucks and commercial vehicles, which often carry heavy loads, torque needs to be transmitted efficiently to ensure adequate traction and pulling power. The differential gears allow the wheels on the same axle to rotate at different speeds, accommodating varying traction conditions and load distribution.

- Maneuverability: Heavy-duty trucks and commercial vehicles often need to navigate tight turns and maneuver in confined spaces. The differential gears assist in smooth cornering by allowing the outer wheel to rotate faster than the inner wheel during turns. This differential action helps minimize tire scrubbing and reduces stress on the tires, enhancing maneuverability and reducing wear.

- Traction Control: Differential gears play a critical role in maintaining traction on different road surfaces. In heavy-duty trucks and commercial vehicles that encounter varied terrain, such as off-road conditions or slippery surfaces, the differential gears allow power to be sent to the wheels with the most traction. This helps maximize traction and minimize wheel spin, improving vehicle stability and control.

- Load Sharing: Differential gears facilitate load sharing among multiple axles in heavy-duty trucks and commercial vehicles. Vehicles with multiple axles distribute the load across all axles, reducing stress on individual components and improving overall performance and durability. Differential gears ensure that power is appropriately distributed among the axles, optimizing load sharing and preventing excessive strain on specific wheels or axles.

- Off-Road Capability: Heavy-duty trucks and commercial vehicles often need to operate in challenging off-road conditions. Differential gears, particularly those with advanced features like limited-slip differentials or locking differentials, enhance off-road capability by improving traction and preventing wheel slippage. These differential systems provide additional power to the wheels with traction, enabling the vehicle to navigate through rough terrain more effectively.

- Efficiency and Durability: Differential gears in heavy-duty trucks and commercial vehicles are designed to handle high torque loads and endure demanding operating conditions. They are built with robust materials and precision engineering to ensure durability and long service life. Proper maintenance, including regular inspections and fluid changes, helps maintain the efficiency and performance of the differential gears, contributing to the overall reliability of the vehicle.

In summary, differential gears are indispensable in heavy-duty trucks and commercial vehicles. They enable torque distribution, enhance maneuverability, improve traction control, facilitate load sharing, enhance off-road capability, and contribute to overall efficiency and durability. These gears play a crucial role in ensuring the optimal performance and functionality of heavy-duty and commercial vehicles across various applications and operating conditions.

Are there different types of differential gears available?

Yes, there are different types of differential gears available, each designed to suit specific driving conditions and performance requirements. Here’s an overview of some commonly used types of differential gears:

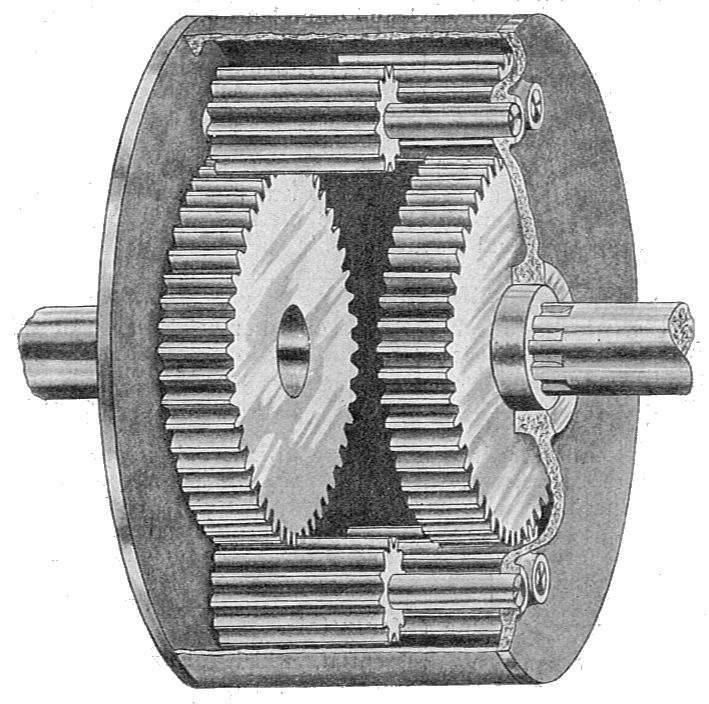

1. Open Differential:

An open differential is the most basic and widely used type of differential gear. It allows the wheels to rotate at different speeds during turns while equally distributing torque. In normal driving conditions, an open differential provides smooth operation and is relatively inexpensive. However, it has limited traction improvement capabilities and may distribute power to the wheel with the least resistance, which can be a disadvantage in low-traction situations.

2. Limited-Slip Differential (LSD):

A limited-slip differential (LSD) improves upon the capabilities of an open differential by providing some degree of torque biasing. LSDs use various mechanisms, such as clutch packs, viscous fluids, or gear arrangements, to transfer more torque to the wheel with better traction. This helps improve traction and power delivery, especially in situations where one wheel has reduced traction. LSDs strike a balance between improved traction and maintaining drivability for everyday use.

3. Electronic Limited-Slip Differential (ELSD):

An electronic limited-slip differential (ELSD) is a modern variation of the limited-slip differential. It incorporates electronic sensors and actuators to actively monitor wheel speeds and traction conditions. The ELSD can quickly and precisely distribute torque to the wheels with better traction, enhancing overall performance and stability. ELSDs are often found in high-performance or advanced all-wheel drive systems.

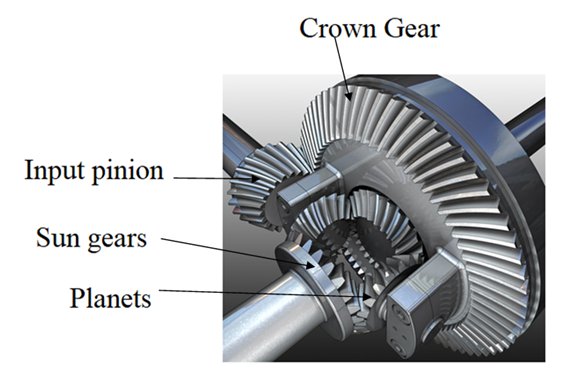

4. Torsen Differential:

A Torsen (short for Torque-Sensing) differential is a type of differential gear that uses a worm gear arrangement to distribute torque. Torsen differentials can provide a higher torque biasing ratio compared to LSDs. They have a mechanical, self-acting design that automatically transfers torque to the wheel with better traction. Torsen differentials are commonly used in performance-oriented vehicles and off-road applications.

5. Locking Differential:

A locking differential is designed to maximize traction in off-road or extreme driving conditions. It allows both wheels to receive an equal amount of torque simultaneously, regardless of traction conditions. Locking differentials can be manually engaged or automatically activated by sensors detecting wheel slip. While locking differentials enhance traction, they can also negatively impact handling on paved surfaces, making them more suitable for off-road or specialized applications.

6. Torque Vectoring Differential:

A torque vectoring differential is a more advanced type of differential that actively distributes torque to individual wheels to enhance vehicle dynamics. It uses electronic systems to monitor various vehicle parameters, such as wheel speed, steering input, and lateral acceleration. By selectively applying torque to specific wheels, torque vectoring differentials can improve cornering performance, stability, and agility.

These are just a few examples of the different types of differential gears available. Each type offers unique characteristics and advantages, allowing vehicle manufacturers to tailor the differential system to specific driving conditions, performance requirements, and driver preferences.

editor by Dream 2024-05-09

China Standard Differential Washer Sider Auto Gear Txz6782 for Hino gear cycle

Product Description

Product Description

| 1. High quality materials, professional production, high-precision equipment. Customized design and processing; |

| 2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties; |

| 3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption; |

| 4. Focus on gear processing for 35 years. |

| 5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity; |

| 6. The tooth surface can be ground, and the precision is higher after grinding. |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

ZheJiang Province Tonging Auto Synchronizer Co., Ltd and ZheJiang Shshi Xihu (West Lake) Dis.g Gears Co. Ltd are focus on the production of space parts for the CHINAMFG over 35years. a professional company in the field.

Our spare parts are interchangeable with the major manufacturers of heavy duty trucks, buses, light commercial and 4×4 pick up vehicles, medium and heavy duty Japanese applications. New items developing for customized in earthmover and agriculture machines.

There are 1 forging production line of 1600 tons, several forging production lines from 400 tons to 1000 tons: more than 300 various manufacturing and inspecting equipments with high efficiency and precision; 2 heat treatment production lines.

Our company can achieve more production process of forging, hobbing, shaving, gear

shaping, grinding and heat treatment.

There are 4 factories affiliated to the company, including Gear Factory, Synchronizer Factory, Adjusting Arm Factory and Casting Factory, producing various Transmission Synchronizers;

Differential Gears; Cross Spiders; Differential cases and other parts. We produce those parts for various types of

domestic trucks, Japanese trucks, European trucks and other famous brands. Moreover, the Agriculture machinery gears and Engineering machinery gears can developing also.

As a member of China Gear Industry Association and China

Auto Gear Manufacture Association, our company always focuses

on technology and quality. The company is an AAA enterprise, got lATF16949:2016 Quality Management System Certificate and has been awarded as Honest and Faithful Company several times by

government. Our products occupy large share of China and we established cooperation relations with CHINAMFG Group. Meanwhile, our products become very popular in Southeast Asia, Europe. Middle

East, Russia, America and other foreign countries.

With superior quality and excellent service, we are ready to offer

our products and service to costumers of all over the world!

Material: 20CrMnTiH

Scope and Capability of Gear Processing:

Modulus 1 to 10

Grade 6 of grinding accuracy

Grade 8 of accuracy achieved by shaving

Maximum machining diameter 400mm

Heat treatment: Quenching and tempering +carburizing

Gearboxes

Input shafts

Gears

Sliding sleeves

Hubs and synchronizer cones

Planet carriers

Housing

Differentials

Loaded differential cases

Idler pinions and side gears

Gears

Differential kits

Differential Input Shafts

FAQ

| Q1. What is your terms of packing? |

| A: Generally, we pack our goods in Crates/Pallet/Boxes/Cartons. |

| Q2. How about your delivery time? |

| A: Generally, it is 3-7days if the goods are in stock,or it is need 20-30days to producing, |

| it is according to the quantity. |

| Q3. Can you produce according to the samples? |

| A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures. |

| Q4. Do you test all your goods before delivery? |

| A: Yes, we have 100% test before delivery |

| Q5.Do you provide samples?is it free or extra? |

| A:yes,we could offer the sample for free,but do not pay the cost of freight. |

| Q6.What is your term of payment |

| A:payment less than 3000usd,100% in advance,payment more than 6000usd,30%payment before produce,70% balance payment before shipment. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a differential gear system contribute to tire longevity?

A differential gear system plays a crucial role in tire longevity by ensuring optimal traction, minimizing tire wear, and distributing torque effectively. Here’s a detailed explanation of how a differential gear system contributes to tire longevity:

- 1. Traction Optimization: The differential gear system allows the wheels on the same axle to rotate at different speeds when the vehicle is turning. This capability helps improve traction and reduces tire scrubbing, which occurs when the tires resist turning and skid instead. By optimizing traction during turns, the differential gear system helps prevent excessive tire wear caused by scrubbing.

- 2. Torque Distribution: The differential gear system distributes torque from the engine to the wheels, allowing each wheel to receive an appropriate amount of power based on traction conditions. This distribution helps prevent wheel spin and excessive tire wear. By ensuring that torque is evenly distributed, the differential gear system helps maintain balanced tire wear across all wheels.

- 3. Wheel Speed Synchronization: When driving in a straight line, the differential gear system synchronizes the rotational speeds of the wheels. This synchronization minimizes tire scrubbing and reduces uneven wear. By keeping the wheels rotating at similar speeds, the differential gear system promotes even tire wear, extending tire longevity.

- 4. Cornering Stability: During cornering, the differential gear system allows the outer wheel to rotate faster than the inner wheel. This speed difference is necessary to accommodate the varying distances each wheel travels around the curve. By enabling smooth and controlled cornering, the differential gear system helps prevent excessive tire wear caused by lateral forces.

- 5. Reduced Stress on Tires: A properly functioning differential gear system helps reduce stress on tires by allowing them to rotate freely and independently. By mitigating excessive forces and minimizing tire scrubbing, the differential gear system helps decrease wear and tear on the tires. This reduction in stress contributes to prolonged tire life.

- 6. Traction Control: Some modern vehicles are equipped with advanced differential systems, such as electronic limited-slip differentials or torque vectoring differentials. These systems actively manage torque distribution to individual wheels based on traction conditions. By optimizing traction control, these differential systems help minimize tire slippage, improve grip, and reduce tire wear.

- 7. Proper Maintenance: Regular maintenance of the differential gear system is essential for tire longevity. This includes periodic inspection of the differential components, ensuring proper lubrication, and addressing any issues promptly. Well-maintained differentials help ensure optimal performance, reducing the risk of tire wear and extending tire life.

Overall, a well-functioning and properly maintained differential gear system plays a vital role in tire longevity. It optimizes traction, distributes torque effectively, synchronizes wheel speeds, promotes cornering stability, and reduces stress on tires. By understanding and maintaining the differential gear system, drivers can help maximize tire life and minimize the need for premature tire replacements.

How do differential gears interact with the suspension system of a vehicle?

Differential gears interact with the suspension system of a vehicle in several ways. Here’s a detailed explanation of their interaction:

- Power Transmission: The primary function of differential gears is to distribute power from the engine to the wheels. The power is transmitted through the drivetrain, which includes the transmission, driveshaft, and differential gears. The differential gears are located within the rear axle assembly and connect to the wheels via the axle shafts. As the suspension system allows the wheels to move up and down independently, the differential gears accommodate these movements to ensure smooth and consistent power transmission.

- Wheel Movement: The suspension system of a vehicle allows the wheels to move vertically to absorb road irregularities, bumps, and vibrations. This movement is essential for providing a comfortable ride, maintaining tire contact with the road surface, and improving overall handling and stability. The differential gears must accommodate this wheel movement without hindering power transmission. They are mounted within the axle housing, which is connected to the suspension system, allowing the wheels to move up and down while maintaining their connection to the differential assembly.

- Drive Axle and Halfshafts: In many vehicles, the differential gears are located within the drive axle assembly, which is an integral part of the suspension system. The drive axle assembly consists of the differential gears, axle housing, and halfshafts (also known as axle shafts). The halfshafts connect the differential gears to the wheel hubs, transmitting power from the differential to the wheels. The suspension system and differential gears work in conjunction to allow the halfshafts to flex and accommodate the vertical movement of the wheels while maintaining power delivery.

- Torque Steer: Differential gears can also influence torque steer, which is the tendency of the vehicle to pull to one side during acceleration. Torque steer occurs when one wheel receives more torque than the other, causing an imbalance in power delivery and resulting in steering effects. Differential gears, particularly in front-wheel-drive vehicles, help manage torque steer by distributing torque between the front wheels. Advanced differential technologies, such as limited-slip differentials or electronic torque vectoring systems, can further mitigate torque steer and enhance overall vehicle stability.

- Performance Applications: In high-performance or sport-oriented vehicles, the interaction between differential gears and the suspension system becomes even more critical. The suspension system is usually designed to provide optimal handling characteristics, including minimal body roll, precise cornering, and responsive feedback. Differential gears, particularly limited-slip differentials or electronically controlled differentials, can be specifically tuned to complement the suspension system and maximize traction, stability, and cornering performance. This integration ensures that the power delivered to the wheels is effectively utilized, enhancing the vehicle’s overall dynamic capabilities.

In summary, differential gears interact with the suspension system of a vehicle by accommodating wheel movement, transmitting power while allowing independent wheel motion, connecting to the drive axle and halfshafts, managing torque steer, and optimizing performance in high-performance applications. This interaction ensures smooth power transmission, proper handling, stability, and overall vehicle performance.

How does a limited-slip differential differ from an open differential?

A limited-slip differential (LSD) differs from an open differential in several key ways. Here’s a detailed explanation:

1. Torque Distribution:

In an open differential, torque is distributed equally between the two wheels. When both wheels have good traction, this distribution works well. However, if one wheel loses traction, the open differential will send more power to that wheel, causing it to spin while the other wheel receives minimal power. This can result in reduced traction and compromised performance.

In contrast, a limited-slip differential actively biases torque distribution. It uses various mechanisms, such as clutch packs, viscous fluids, or gear arrangements, to transfer more torque to the wheel with better traction. This torque biasing helps improve traction and power delivery, especially in situations where one wheel has reduced traction. By providing a more balanced torque distribution, a limited-slip differential enhances overall performance and stability.

2. Traction Improvement:

One of the primary advantages of a limited-slip differential is its ability to improve traction compared to an open differential. When one wheel encounters reduced traction, such as on slippery surfaces or during cornering, the limited-slip differential transfers more torque to the wheel with better traction. This helps maximize the vehicle’s ability to maintain forward motion and improves overall stability by minimizing wheel slip. In contrast, an open differential may distribute power to the wheel with the least resistance, resulting in reduced traction and compromised handling.

3. Drivability:

In terms of drivability, open differentials are generally smoother and more predictable. They allow the wheels to rotate at different speeds during turns, facilitating smooth operation and minimizing binding or tire scrubbing. Open differentials are also less expensive to manufacture, making them a common choice for everyday vehicles.

On the other hand, limited-slip differentials offer improved drivability compared to open differentials, especially in situations with varying traction conditions. Limited-slip differentials strike a balance between improved traction and maintaining drivability for everyday use. They can provide better control and stability during acceleration, cornering, and challenging road conditions.

4. Performance and Handling:

Limited-slip differentials are often favored in performance-oriented vehicles or applications that require enhanced handling characteristics. The ability to transfer torque to the wheel with better traction helps optimize power delivery, reduce wheel slip, and improve overall performance. Limited-slip differentials can enhance cornering ability, stability, and agility, allowing drivers to navigate curves and corners with more confidence and control.

In contrast, open differentials may be more prone to wheel slip, particularly in high-performance or demanding driving situations. This can result in compromised performance and reduced stability.

In summary, a limited-slip differential differs from an open differential in terms of torque distribution, traction improvement, drivability, and performance. By actively biasing torque distribution and improving traction, a limited-slip differential offers better performance and handling characteristics, especially in challenging driving conditions.

editor by Dream 2024-05-08

China manufacturer CE0042m0-9 Rear Axle Half Shaft Gear for CZPT Truck Spare Parts Differential Gear hypoid bevel gear

Product Description

High Quality CE0042M0-9 Rear Axle Half Shaft Gear For CHINAMFG Truck Spare Parts Differential Gear

Detailed Photos

Product advantages & features

(1) Forged with 20crmoti and finely ground teeth.

(2) OEM status: CHINAMFG Axle, CHINAMFG Truck.

(3) Self inspection, patrol inspection and completion inspection to ensure 100% pass rate of products.

Factory Show

Brand Culture

Packaging & Shipping

Working Principle

Function of gear transmission

1.Variable speed: By meshing 2 gears of different sizes, the speed of the gears can be changed. For example, the gearbox gear can reduce or increase the speed from the engine to meet the needs of the car;

2.Torque change: The meshing of 2 gears of different sizes changes the transmitted torque while changing the speed of the gears. For example, the car gearbox, the main reducer in the drive axle, can change the torque of the car;

3.Change direction: the power action direction of some vehicle engines is perpendicular to the driving direction of the vehicle. The transmission direction of power must be changed to drive the vehicle. This device is usually the main reducer and differential of the car.

Gear transmission has the advantages of high transmission efficiency, compact structure, reliable gear transmission, long service life and stable transmission ratio. Its transmission efficiency can reach 99%. Among the commonly used mechanical transmissions, gear transmission has high efficiency; its disadvantage is that compared with belt transmission and chain transmission, the manufacturing and installation accuracy of gears are high, and the price is more expensive. It is not suitable for transmission with too large distance between shafts.

Basic types of gear transmissions

| Gear drive | Plane gear transmission | Spur gear drive | Inner Meshing |

| External Meshing | |||

| Rack and pinion | |||

| Helical Gear Drive | Inner Meshing | ||

| External Meshing | |||

| Rack and pinion | |||

| Herringbone gear movement | |||

| Space gear transmission | Transfer intersecting motion | Spur gear | |

| Helical gear | |||

| Curved gear | |||

| Transfer staggered axis motion | Crossed helical gear transmission | ||

| Worm turbine | |||

| Hypoid gear |

Spur gear and helical gear

Spur gears enter and exit meshing along the whole tooth width at the same time. Its transmission efficiency is very high. Its disadvantages are poor stability, impact and noise.

The tooth meshing process of helical gear is longer than that of spur gear, and the number of teeth participating in meshing is also more than that of spur gear. Therefore, the helical gear transmission is stable, the bearing capacity is strong, and the noise and impact are small. The main disadvantage of helical gear is that the axial component force will be generated when the helical gear surface is subjected to the normal force, and the thrust bearing needs to be installed, which complicates the structure.

Lubrication of gear transmission

There is relative sliding and friction between gear transmission tooth surfaces, which will cause tooth surface wear, increase transmission power consumption and reduce transmission efficiency. Therefore, lubricant must be used to reduce wear and accelerate heat dissipation. This lubricant is gear oil. Different kinds of gears on the car are lubricated with different gear oils, which must not be added wrong. For example, automatic transmission oil and CVT transmission oil cannot be mixed.

Honor Certificate

FAQ

Q1. Are you a factory or trading company?

We are a factory integrating research, development, production and sales.

Q2. What are the advantages of your products?

We support product customization to meet customer needs for special products. We can strictly control the products from raw materials to production, processing, product quality inspection, delivery, packaging, etc., and provide customers with high-end products and the most advantageous prices.

Q3. How about products price?

We are a factory, all products are direct sale at factory price. For the same price, we will provide the best quality; for the same quality, we have the most advantageous price.

Q4. What is your terms of packing?

We have branded packaging and neutral packaging, and we can also do what you want with authorization. This is flexible.

Q5. How to guarantee your after-sales service?

Strict inspection during production, Strictly check the products before shipment to ensure our packaging in good condition. Track and receive feedback from customer regularly. Our products warranty is 365 days.

Each product provides quality assurance service. If there is a problem with the product within the warranty period, the customer can negotiate with us in detail about the related claims, and we will do our best to satisfy the customer.

Q6. How can I accurately buy the products I need?

We need accurate product number, If you can’t provide product number, you can send us your product picture, or tell us your truck model, engine name plate, and so on. we will

determine exactly what you need products.

Q7. Do you accept third party inspection?

Yes.we do

Q8. How about your delivery time?

Generally, it will take 3 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q9. What are your brand agency conditions and advantages?

After we CHINAMFG an agent in 1 city, we will not CHINAMFG a second company to protect the agent’s brand advantage and price advantage. And we will help the agent develop customers and solve all kinds of difficult and miscellaneous problems about products.

Q10. What is your terms of payment?

By TT or LC. We’ll show you the photos of the products and packages before you pay the balance.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Support |

|---|---|

| Warranty: | 12 Months |

| Type: | Truck Gear |

| Samples: |

US$ 75/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of vehicles that use differential gears?

Differential gears are utilized in various types of vehicles to enable smooth and efficient power distribution to the wheels. Here are some examples of vehicles that use differential gears:

1. Passenger Cars:

Most passenger cars, including sedans, hatchbacks, and SUVs, are equipped with differential gears. These gears are typically found in the rear axle of rear-wheel-drive vehicles or in both the front and rear axles of all-wheel-drive vehicles. Differential gears allow the wheels to rotate at different speeds while maintaining power transfer, ensuring smooth cornering and traction on different road surfaces.

2. Trucks and Pickup Trucks:

Trucks and pickup trucks commonly employ differential gears to enhance their performance, especially for towing, hauling, and off-road applications. Rear-wheel-drive trucks utilize differential gears in the rear axle, while many modern trucks also feature all-wheel-drive or four-wheel-drive systems with differential gears in both the front and rear axles. These differential gears enable improved traction, power distribution, and maneuverability in various driving conditions.

3. SUVs and Crossovers:

Sport utility vehicles (SUVs) and crossovers often incorporate differential gears to provide enhanced off-road capability and all-weather performance. Many SUVs are equipped with all-wheel-drive or four-wheel-drive systems that utilize differential gears in the front and rear axles. These gears allow power transfer between the wheels and enable optimal traction on different terrains, making SUVs well-suited for off-road adventures and challenging driving conditions.

4. Sports Cars and Performance Vehicles:

Sports cars and high-performance vehicles often employ advanced differential systems for improved handling, stability, and performance. Examples include limited-slip differentials, electronic differentials, or torque vectoring differentials. These systems use differential gears in combination with advanced technologies to distribute torque to the wheels based on driving conditions, enhancing traction, cornering ability, and overall vehicle dynamics.

5. Off-Road Vehicles and SUVs:

Differential gears are essential components in off-road vehicles designed for rugged terrains and extreme driving conditions. Vehicles such as dedicated off-road SUVs, trucks, and specialized off-road vehicles like Jeeps and Land Rovers utilize differential gears, including locking differentials, to maximize traction and improve off-road performance. These gears allow for better wheel articulation, independent wheel movement, and power distribution to overcome obstacles and maintain traction on challenging off-road trails.

6. Commercial and Heavy-Duty Vehicles:

Commercial trucks, buses, and heavy-duty vehicles utilize differential gears to handle the demands of heavy loads and challenging driving conditions. Differential gears in these vehicles help distribute torque to the drive wheels efficiently, ensuring better traction, stability, and power transfer. They are critical for the performance and safety of large commercial vehicles that operate under varying load and road conditions.

7. Racing Cars:

In racing, differential gears play a vital role in enhancing performance and handling characteristics. High-performance racing cars, including Formula 1 cars, rally cars, and sports prototypes, utilize advanced differential systems that allow precise control of power distribution to optimize acceleration, cornering, and stability during high-speed maneuvers.

In summary, differential gears are utilized in a wide range of vehicles, including passenger cars, trucks, SUVs, sports cars, off-road vehicles, commercial vehicles, and racing cars. These gears are integral to achieving optimal power distribution, traction, and maneuverability in various driving conditions and applications.

How do differential gears function in both front-wheel-drive and rear-wheel-drive vehicles?

In both front-wheel-drive and rear-wheel-drive vehicles, differential gears serve the same fundamental purpose of distributing power from the engine to the wheels while allowing them to rotate at different speeds. However, their specific configurations and functions differ between these two types of drivetrains. Here’s a detailed explanation of how differential gears function in both front-wheel-drive and rear-wheel-drive vehicles:

Front-Wheel-Drive Vehicles:

In front-wheel-drive vehicles, the differential gears are typically integrated into the transaxle assembly, which combines the transmission and differential into a single unit. Here’s how the differential gears function in front-wheel-drive vehicles:

- Power Input: The engine’s power is transmitted through the transmission to the transaxle assembly.

- Ring and Pinion Gears: The power from the transaxle is delivered to a set of ring and pinion gears within the differential assembly. These gears are responsible for distributing torque to the front wheels.

- Spider Gears: The ring gear is connected to a carrier that houses multiple smaller gears called spider gears. These spider gears allow the front wheels to rotate at different speeds during turns.

- Equal Torque Distribution: In front-wheel-drive vehicles, the differential gears prioritize equal torque distribution between the two front wheels. This design helps maintain traction and stability during acceleration and cornering.

- Traction Control: Some front-wheel-drive vehicles may also incorporate additional features in the differential assembly, such as electronic limited-slip differentials or traction control systems. These features help optimize traction by transferring power to the wheel with better grip, reducing wheel spin and improving overall performance.

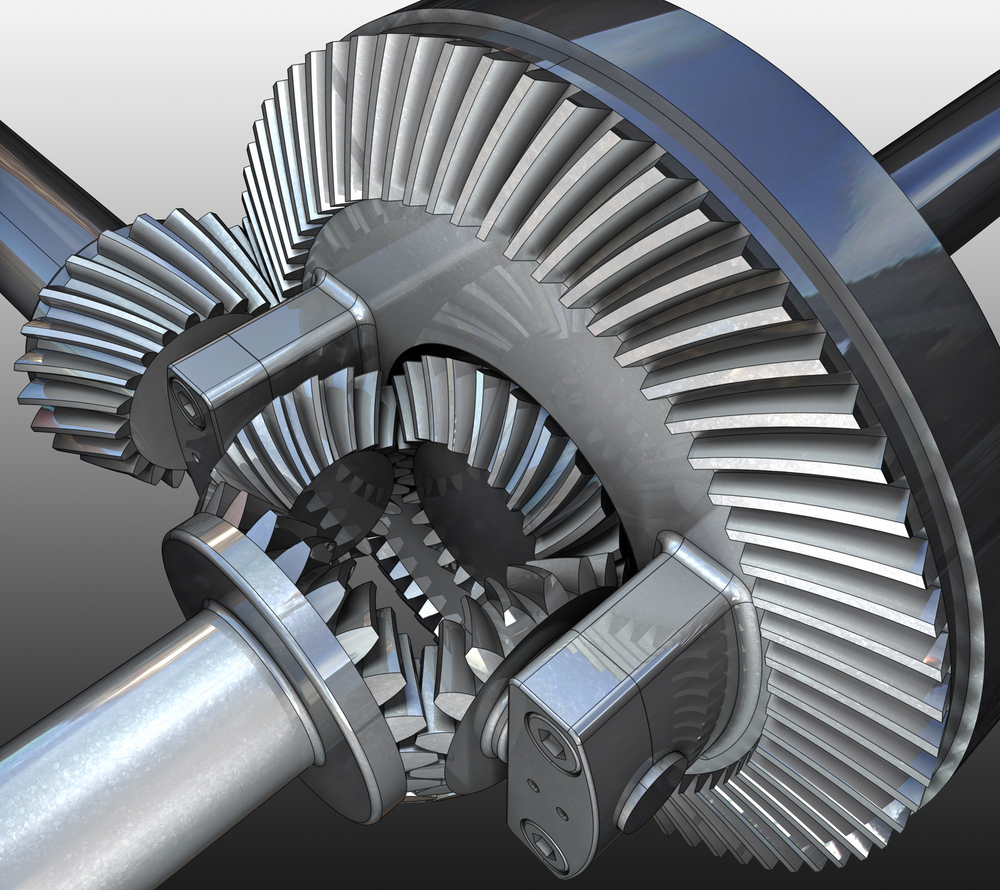

Rear-Wheel-Drive Vehicles:

In rear-wheel-drive vehicles, the differential gears are typically located in the rear axle assembly. Here’s how the differential gears function in rear-wheel-drive vehicles:

- Power Input: The engine’s power is transmitted through the transmission to the driveshaft, which connects to the rear axle assembly.

- Drive Pinion and Ring Gear: The driveshaft is connected to a drive pinion gear, which meshes with a larger ring gear. This gear set is responsible for transferring power to the rear wheels.

- Spider Gears: Similar to front-wheel-drive vehicles, rear-wheel-drive vehicles also have spider gears housed within the differential assembly. The spider gears allow the rear wheels to rotate at different speeds during turns.

- Torque Distribution: In rear-wheel-drive vehicles, the differential gears distribute torque to the rear wheels in a manner that prioritizes rear-wheel traction and propulsion. This configuration is particularly beneficial for vehicle acceleration and load-carrying capability.

- Enhanced Features: Rear-wheel-drive vehicles may also incorporate advanced differential systems, such as limited-slip differentials or electronic locking differentials, to optimize traction and performance. These features help improve grip, especially in challenging driving conditions or when driving off-road.

In summary, differential gears function differently in front-wheel-drive and rear-wheel-drive vehicles due to their distinct drivetrain configurations. In front-wheel-drive vehicles, the differential gears are typically integrated into the transaxle assembly and prioritize equal torque distribution to the front wheels. In rear-wheel-drive vehicles, the differential gears are located in the rear axle assembly and focus on torque distribution to the rear wheels for propulsion. Understanding the specific functions of differential gears in each drivetrain type is essential for optimizing vehicle performance, traction, and stability.

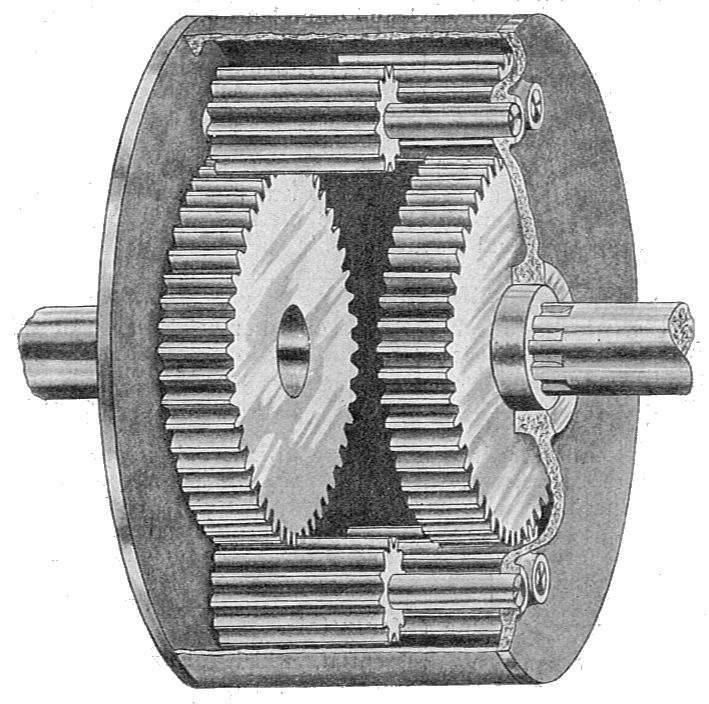

Can you explain the concept of torque distribution in a differential gear?

Torque distribution is a fundamental concept in a differential gear that refers to the way rotational force is distributed among the wheels of a vehicle. Here’s a detailed explanation:

In a vehicle equipped with a differential gear, torque is transmitted from the engine to the differential, and then further distributed to the wheels. The differential gear ensures that torque is divided between the wheels, allowing them to receive power and propel the vehicle forward.

1. Power Input:

The torque distribution process begins with the power input from the engine. The engine generates rotational force, or torque, which is transmitted through the drivetrain to the differential gear.

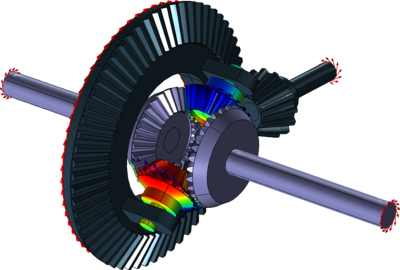

2. Differential Assembly:

Within the differential gear, torque is distributed among several components, including the ring gear, pinion gear, side gears, and spider gears. The specific arrangement may differ depending on the type of differential used.

3. Side Gears and Spider Gears:

The side gears are connected to the axle shafts, which extend to the wheels. The spider gears, also known as planetary gears, are positioned between the side gears. When torque is applied to the differential assembly, it is transferred to the side gears through the spider gears.

4. Equal Torque Distribution:

In a straight-line driving scenario, where both wheels have equal traction and are rotating at the same speed, the spider gears rotate freely on their respective shafts. This allows the side gears to rotate at the same speed as the differential case, resulting in equal torque distribution to both wheels. As a result, both wheels receive an equal share of power from the differential.

5. Unequal Torque Distribution:

During turns or when one wheel encounters different traction conditions, the wheels need to rotate at different speeds. In this situation, the spider gears are forced to rotate along with the side gears due to the difference in rotational speeds between the two wheels.

As the spider gears rotate, they allow the side gears to rotate at different speeds, compensating for the variation in wheel speeds. This results in unequal torque distribution, with the outer wheel (on the outside of the turn) receiving more torque and the inner wheel (on the inside of the turn) receiving less torque. The differential gear enables this torque differentiation, ensuring that the wheels can rotate independently while still receiving power from the differential.

6. Optimizing Traction:

The torque distribution in a differential gear plays a crucial role in optimizing traction. Unequal torque distribution allows the wheel with better traction to receive more power, maximizing the vehicle’s ability to maintain forward motion. This is particularly beneficial in situations where one wheel is on a slippery surface or encounters reduced traction conditions.

7. Differential Types:

It’s important to note that different types of differentials can provide varying torque distribution characteristics. For example, open differentials primarily distribute torque equally, while limited-slip differentials and locking differentials offer varying degrees of torque biasing to improve traction in specific conditions.

In summary, torque distribution in a differential gear refers to the division of rotational force among the wheels of a vehicle. The differential gear enables equal torque distribution during straight-line driving and unequal torque distribution during turns or varied traction conditions. By optimizing torque distribution, the differential gear ensures efficient power delivery, traction optimization, and overall performance of the vehicle.

editor by Dream 2024-05-08

China wholesaler Transmission Gear/Drive Gear/Planetary Gear/Wheel Gear/Differential Gear wholesaler

Product Description

Our advantage:

*Specialization in CNC formulations of high precision and quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Online orders and production progress monitoring

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

*Manufacturing of complex components of 1 – 1000mm.

Production machine:

| Specification | Material | Hardness |

| Z13 | Steel | HRC35-40 |

| Z16 | Steel | HRC35-40 |

| Z18 | Steel | HRC35-40 |

| Z20 | Steel | HRC35-40 |

| Z26 | Steel | HRC35-40 |

| Z28 | Steel | HRC35-40 |

| Custom dimensions according to drawings | Steel | HRC35-40 |

Production machine:

Inspection equipment :

Gear tester

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

How does a differential gear system contribute to tire longevity?

A differential gear system plays a crucial role in tire longevity by ensuring optimal traction, minimizing tire wear, and distributing torque effectively. Here’s a detailed explanation of how a differential gear system contributes to tire longevity:

- 1. Traction Optimization: The differential gear system allows the wheels on the same axle to rotate at different speeds when the vehicle is turning. This capability helps improve traction and reduces tire scrubbing, which occurs when the tires resist turning and skid instead. By optimizing traction during turns, the differential gear system helps prevent excessive tire wear caused by scrubbing.

- 2. Torque Distribution: The differential gear system distributes torque from the engine to the wheels, allowing each wheel to receive an appropriate amount of power based on traction conditions. This distribution helps prevent wheel spin and excessive tire wear. By ensuring that torque is evenly distributed, the differential gear system helps maintain balanced tire wear across all wheels.

- 3. Wheel Speed Synchronization: When driving in a straight line, the differential gear system synchronizes the rotational speeds of the wheels. This synchronization minimizes tire scrubbing and reduces uneven wear. By keeping the wheels rotating at similar speeds, the differential gear system promotes even tire wear, extending tire longevity.

- 4. Cornering Stability: During cornering, the differential gear system allows the outer wheel to rotate faster than the inner wheel. This speed difference is necessary to accommodate the varying distances each wheel travels around the curve. By enabling smooth and controlled cornering, the differential gear system helps prevent excessive tire wear caused by lateral forces.

- 5. Reduced Stress on Tires: A properly functioning differential gear system helps reduce stress on tires by allowing them to rotate freely and independently. By mitigating excessive forces and minimizing tire scrubbing, the differential gear system helps decrease wear and tear on the tires. This reduction in stress contributes to prolonged tire life.

- 6. Traction Control: Some modern vehicles are equipped with advanced differential systems, such as electronic limited-slip differentials or torque vectoring differentials. These systems actively manage torque distribution to individual wheels based on traction conditions. By optimizing traction control, these differential systems help minimize tire slippage, improve grip, and reduce tire wear.

- 7. Proper Maintenance: Regular maintenance of the differential gear system is essential for tire longevity. This includes periodic inspection of the differential components, ensuring proper lubrication, and addressing any issues promptly. Well-maintained differentials help ensure optimal performance, reducing the risk of tire wear and extending tire life.

Overall, a well-functioning and properly maintained differential gear system plays a vital role in tire longevity. It optimizes traction, distributes torque effectively, synchronizes wheel speeds, promotes cornering stability, and reduces stress on tires. By understanding and maintaining the differential gear system, drivers can help maximize tire life and minimize the need for premature tire replacements.

What is the role of a center differential in all-wheel-drive systems?

In an all-wheel-drive (AWD) system, the center differential plays a crucial role in distributing power between the front and rear wheels. It is responsible for managing torque transfer and ensuring optimal traction and stability in various driving conditions. Here’s a detailed explanation of the role of a center differential in all-wheel-drive systems:

- Torque Distribution: The center differential’s primary function is to distribute torque between the front and rear axles in an AWD system. It receives power from the engine and transmits it to both the front and rear wheels. The distribution of torque can vary depending on the design and capabilities of the center differential.

- Power Split: The center differential splits the engine’s power between the front and rear axles in a manner that optimizes traction and stability. Under normal driving conditions, it typically distributes torque evenly, providing balanced power to all wheels. This balanced power distribution helps enhance vehicle control and stability.

- Variable Torque Split: In some AWD systems, the center differential can vary the torque split based on driving conditions. It can adjust the distribution of power between the front and rear axles to optimize traction and handling. For example, if the system detects slippage in the front wheels, it can transfer more torque to the rear wheels to improve traction and maintain vehicle stability.

- Traction Enhancement: The center differential helps improve traction by allowing the front and rear wheels to rotate at different speeds. This capability is particularly beneficial in situations where the left and right wheels on the same axle encounter varying levels of grip, such as when driving on slippery or uneven surfaces. By allowing the wheels to rotate at different speeds, the center differential enables the wheels with better traction to receive more power, enhancing overall grip and traction.

- Adaptability to Different Conditions: A well-designed center differential enables an AWD system to adapt to different driving conditions. Whether it’s driving on dry pavement, wet roads, icy surfaces, or off-road terrain, the center differential helps optimize power distribution to maintain traction and stability. It allows the AWD system to provide enhanced grip and control, regardless of the prevailing driving conditions.

- Integration with Other Systems: The center differential often works in conjunction with other vehicle systems to further enhance performance and safety. For example, some AWD systems incorporate electronic controls that can interact with the vehicle’s stability control system, traction control system, or other safety features. This integration helps optimize power delivery, traction management, and overall vehicle dynamics.

In summary, the center differential plays a critical role in all-wheel-drive systems. It distributes torque between the front and rear axles, enhances traction and stability, adapts to different driving conditions, and integrates with other vehicle systems. By effectively managing torque transfer, the center differential helps maximize grip, improve handling, and enhance overall performance in AWD vehicles.

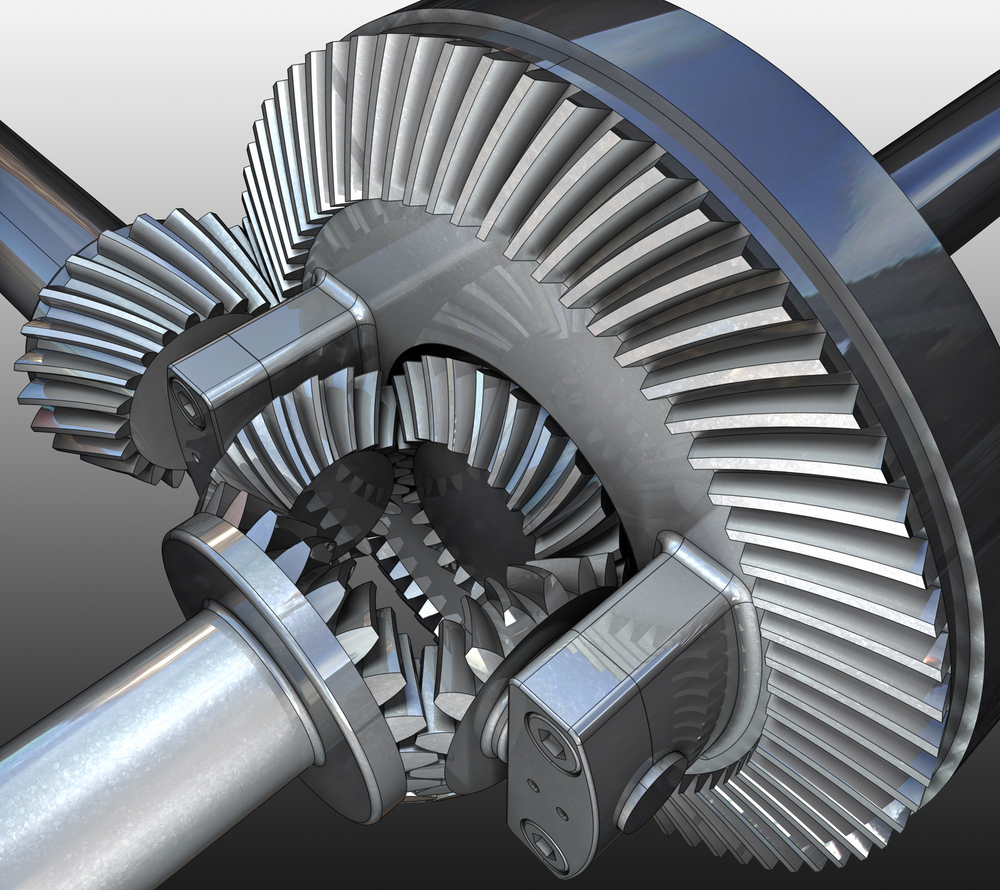

What is the purpose of using a differential gear in an automobile?

A differential gear serves a crucial purpose in an automobile. Here’s a detailed explanation:

The purpose of using a differential gear in an automobile is to allow the wheels to rotate at different speeds while receiving power from the engine. It enables smooth and controlled maneuvering, optimizes traction, and enhances overall performance. The differential gear plays several key roles in an automobile:

1. Torque Distribution:

One of the primary purposes of a differential gear is to distribute torque (rotational force) from the engine to the wheels. As the engine generates power, the differential ensures that it is transmitted to the wheels efficiently and effectively. By dividing the torque between the two wheels, the differential enables both wheels to receive power and propel the automobile forward.

2. Differential Action:

The differential gear allows the wheels to rotate at different speeds when the automobile is turning or when one wheel encounters different traction conditions. This differential action is crucial for smooth and controlled maneuvering. By enabling the outer wheel to rotate faster than the inner wheel during a turn, the differential allows the automobile to negotiate corners without binding or skidding.

3. Wheel Speed Compensation:

When the automobile is turning, the inside wheel travels a shorter distance compared to the outside wheel. Without a differential gear, this speed difference would cause significant drivetrain stress and tire wear. The differential gear compensates for the varying wheel speeds by allowing the wheels to rotate at different speeds, ensuring smooth operation and minimizing strain on the drivetrain components.

4. Traction Improvement:

In situations where one wheel loses traction, such as when driving on slippery surfaces or uneven terrain, the differential gear helps improve traction. By allowing the wheel with traction to receive more power, the differential ensures that the automobile can continue moving forward. This is particularly important in automobiles with two-wheel drive, as the differential helps optimize power delivery to the wheel with better traction.

5. Reducing Tire Wear:

The differential gear contributes to reducing tire wear by accommodating differences in wheel speeds. By allowing the wheels to rotate at different speeds during turns, the differential minimizes tire scrubbing and uneven wear. It helps distribute the forces evenly across the tires, promoting longer tire life and maintaining better overall traction.

6. Enhanced Stability and Handling:

The differential gear plays a crucial role in enhancing automobile stability and handling. By allowing the wheels to rotate independently, the differential facilitates better control during turns and maneuvering. It helps maintain proper weight distribution, prevents excessive understeer or oversteer, and promotes balanced handling characteristics.

Overall, the purpose of using a differential gear in an automobile is to enable torque distribution, facilitate smooth and controlled maneuvering, optimize traction, reduce tire wear, and enhance stability and handling. The differential gear ensures that power is efficiently delivered to the wheels while accommodating varying speed and traction conditions, resulting in improved performance and driving dynamics.

editor by Dream 2024-05-07

China OEM Reasonable Price Differential Gear Repair Kits for Frr Rear Axle with Good quality

Product Description

Product Description

| product name | side gear/pinion/spider |

| Material | steel |

| Suitable truck model | Isuzu Fsr Frr |

| quality | 100% Professional Test |

| Axle spline teeth | 16/20T |

| Shipping | Sea Transport.Air Transport Air Express |

| Net Weight | 3.6 KGS |

| Gross Weight | 3.8 KGS |

| Warranty | 1 year |

Packing&Shipping

1.Packaging Details:Bubble Bags & Wooden Pallets

2.3-30 days after your order confrimed,100% inspection before shipment.

Our Factory

ZheJiang Youbisheng machinery Co.Ltd. is located in HangZhou HangZhou, China. just 1 hour by car from HangZhou,We are a professional manufacturer of auto parts, set design, development, manufacturing as a professional manufacturer. We focus on a series of fashion accessories, a wide range of diversity, reasonable price and on-time delivery.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in Crates/Pallet/Boxes/Cartons.

Q2. How about your delivery time?

A: Generally, it is 3-7days if the goods are in stock,or it is need 20-30days to producing,

it is according to the quantity.

Q3. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5.Do you provide samples?is it free or extra?

A:yes,we could offer the sample for free,but do not pay the cost of freight.

Q6.What is your term of payment

A:payment less than 3000usd,100% in advance,payment more than 6000usd,30%payment before produce,70% balance payment before shipment.

Contact with us

dear customer,if you are interested in our products,pls feel free contact with us!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Type: | Auto Fasteners |

| Material: | Steel |

| Muffler Type: | Rear Muffler |

| Deck: | Single |

| Product Name: | Differential Planetary Gears |

| Customization: |

Available

| Customized Request |

|---|

How do you maintain and service a differential gear?

Maintaining and servicing a differential gear is crucial to ensure its optimal performance and longevity. Here’s a detailed explanation of the maintenance and servicing process:

1. Regular Inspection:

Perform regular visual inspections of the differential gear to check for any signs of damage, leaks, or excessive wear. Look for oil leaks around the differential housing and inspect the driveshaft, axles, and seals for any signs of damage or leakage. Additionally, listen for any abnormal noises coming from the differential during operation, as they may indicate underlying issues.

2. Fluid Change:

Regularly change the differential fluid as recommended by the vehicle manufacturer. Over time, the fluid can become contaminated with debris, moisture, and metal particles, which can cause accelerated wear and reduced performance. Changing the fluid helps maintain proper lubrication and cooling of the differential gears. Refer to the vehicle’s owner manual or service guide for the recommended fluid type and change intervals.

3. Fluid Level Check:

Check the fluid level in the differential regularly to ensure it is within the recommended range. Use the appropriate method specified by the vehicle manufacturer to check the fluid level, such as a dipstick or inspection plug. Maintaining the correct fluid level is essential for proper lubrication and cooling of the gears.

4. Seal Replacement:

If you notice any leaks or damaged seals, it is important to replace them promptly. Leaking seals can lead to fluid loss, which can cause inadequate lubrication and potential damage to the differential gears. Replace seals as per the manufacturer’s recommendations and ensure proper installation to prevent future leaks.

5. Gear Inspection and Adjustment:

Periodically inspect the gears for signs of wear, damage, or misalignment. If any issues are detected, consult a qualified technician or mechanic for further evaluation and adjustment. Gears that are excessively worn or damaged may need to be replaced to maintain the proper functioning of the differential.

6. Service Differential Components:

Some differential systems have additional components that require servicing. For example, limited-slip differentials may have clutch packs or friction plates that need periodic inspection and maintenance. Follow the manufacturer’s guidelines for servicing these components, which may involve cleaning, lubrication, or replacement as necessary.

7. Professional Servicing:

In addition to regular maintenance tasks, it is recommended to have the differential gear serviced by a professional technician or mechanic at specific intervals or when experiencing significant issues. Professional servicing may involve more in-depth inspections, adjustments, or repairs that require specialized tools and knowledge.

8. Follow Manufacturer Recommendations:

Always refer to the vehicle manufacturer’s recommendations and guidelines for maintaining and servicing the differential gear. They provide specific instructions tailored to your vehicle’s make, model, and differential type, ensuring that you follow the appropriate procedures for optimal performance and longevity.

In summary, maintaining and servicing a differential gear involves regular inspections, fluid changes, fluid level checks, seal replacements, gear inspections and adjustments, servicing of differential components, professional servicing when necessary, and adherence to manufacturer recommendations. By following these steps, you can help ensure the proper functioning and durability of the differential gear in your vehicle.

How do differential gears contribute to traction in slippery conditions?