Product Description

Product Description

| 1. High quality materials, professional production, high-precision equipment. Customized design and processing; |

| 2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties; |

| 3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption; |

| 4. Focus on gear processing for 35 years. |

| 5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity; |

| 6. The tooth surface can be ground, and the precision is higher after grinding. |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

ZheJiang Province Tonging Auto Synchronizer Co., Ltd and ZheJiang Shshi Xihu (West Lake) Dis.g Gears Co. Ltd are focus on the production of space parts for the CHINAMFG over 35years. a professional company in the field.

Our spare parts are interchangeable with the major manufacturers of heavy duty trucks, buses, light commercial and 4×4 pick up vehicles, medium and heavy duty Japanese applications. New items developing for customized in earthmover and agriculture machines.

There are 1 forging production line of 1600 tons, several forging production lines from 400 tons to 1000 tons: more than 300 various manufacturing and inspecting equipments with high efficiency and precision; 2 heat treatment production lines.

Our company can achieve more production process of forging, hobbing, shaving, gear

shaping, grinding and heat treatment.

There are 4 factories affiliated to the company, including Gear Factory, Synchronizer Factory, Adjusting Arm Factory and Casting Factory, producing various Transmission Synchronizers;

Differential Gears; Cross Spiders; Differential cases and other parts. We produce those parts for various types of

domestic trucks, Japanese trucks, European trucks and other famous brands. Moreover, the Agriculture machinery gears and Engineering machinery gears can developing also.

As a member of China Gear Industry Association and China

Auto Gear Manufacture Association, our company always focuses

on technology and quality. The company is an AAA enterprise, got lATF16949:2016 Quality Management System Certificate and has been awarded as Honest and Faithful Company several times by

government. Our products occupy large share of China and we established cooperation relations with CHINAMFG Group. Meanwhile, our products become very popular in Southeast Asia, Europe. Middle

East, Russia, America and other foreign countries.

With superior quality and excellent service, we are ready to offer

our products and service to costumers of all over the world!

Material: 20CrMnTiH

Scope and Capability of Gear Processing:

Modulus 1 to 10

Grade 6 of grinding accuracy

Grade 8 of accuracy achieved by shaving

Maximum machining diameter 400mm

Heat treatment: Quenching and tempering +carburizing

Gearboxes

Input shafts

Gears

Sliding sleeves

Hubs and synchronizer cones

Planet carriers

Housing

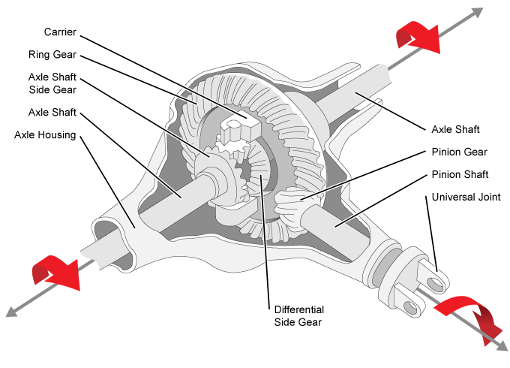

Differentials

Loaded differential cases

Idler pinions and side gears

Gears

Differential kits

Differential Input Shafts

FAQ

| Q1. What is your terms of packing? |

| A: Generally, we pack our goods in Crates/Pallet/Boxes/Cartons. |

| Q2. How about your delivery time? |

| A: Generally, it is 3-7days if the goods are in stock,or it is need 20-30days to producing, |

| it is according to the quantity. |

| Q3. Can you produce according to the samples? |

| A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures. |

| Q4. Do you test all your goods before delivery? |

| A: Yes, we have 100% test before delivery |

| Q5.Do you provide samples?is it free or extra? |

| A:yes,we could offer the sample for free,but do not pay the cost of freight. |

| Q6.What is your term of payment |

| A:payment less than 3000usd,100% in advance,payment more than 6000usd,30%payment before produce,70% balance payment before shipment. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does a differential gear system contribute to tire longevity?

A differential gear system plays a crucial role in tire longevity by ensuring optimal traction, minimizing tire wear, and distributing torque effectively. Here’s a detailed explanation of how a differential gear system contributes to tire longevity:

- 1. Traction Optimization: The differential gear system allows the wheels on the same axle to rotate at different speeds when the vehicle is turning. This capability helps improve traction and reduces tire scrubbing, which occurs when the tires resist turning and skid instead. By optimizing traction during turns, the differential gear system helps prevent excessive tire wear caused by scrubbing.

- 2. Torque Distribution: The differential gear system distributes torque from the engine to the wheels, allowing each wheel to receive an appropriate amount of power based on traction conditions. This distribution helps prevent wheel spin and excessive tire wear. By ensuring that torque is evenly distributed, the differential gear system helps maintain balanced tire wear across all wheels.

- 3. Wheel Speed Synchronization: When driving in a straight line, the differential gear system synchronizes the rotational speeds of the wheels. This synchronization minimizes tire scrubbing and reduces uneven wear. By keeping the wheels rotating at similar speeds, the differential gear system promotes even tire wear, extending tire longevity.

- 4. Cornering Stability: During cornering, the differential gear system allows the outer wheel to rotate faster than the inner wheel. This speed difference is necessary to accommodate the varying distances each wheel travels around the curve. By enabling smooth and controlled cornering, the differential gear system helps prevent excessive tire wear caused by lateral forces.

- 5. Reduced Stress on Tires: A properly functioning differential gear system helps reduce stress on tires by allowing them to rotate freely and independently. By mitigating excessive forces and minimizing tire scrubbing, the differential gear system helps decrease wear and tear on the tires. This reduction in stress contributes to prolonged tire life.

- 6. Traction Control: Some modern vehicles are equipped with advanced differential systems, such as electronic limited-slip differentials or torque vectoring differentials. These systems actively manage torque distribution to individual wheels based on traction conditions. By optimizing traction control, these differential systems help minimize tire slippage, improve grip, and reduce tire wear.

- 7. Proper Maintenance: Regular maintenance of the differential gear system is essential for tire longevity. This includes periodic inspection of the differential components, ensuring proper lubrication, and addressing any issues promptly. Well-maintained differentials help ensure optimal performance, reducing the risk of tire wear and extending tire life.

Overall, a well-functioning and properly maintained differential gear system plays a vital role in tire longevity. It optimizes traction, distributes torque effectively, synchronizes wheel speeds, promotes cornering stability, and reduces stress on tires. By understanding and maintaining the differential gear system, drivers can help maximize tire life and minimize the need for premature tire replacements.

How do differential gears interact with the suspension system of a vehicle?

Differential gears interact with the suspension system of a vehicle in several ways. Here’s a detailed explanation of their interaction:

- Power Transmission: The primary function of differential gears is to distribute power from the engine to the wheels. The power is transmitted through the drivetrain, which includes the transmission, driveshaft, and differential gears. The differential gears are located within the rear axle assembly and connect to the wheels via the axle shafts. As the suspension system allows the wheels to move up and down independently, the differential gears accommodate these movements to ensure smooth and consistent power transmission.

- Wheel Movement: The suspension system of a vehicle allows the wheels to move vertically to absorb road irregularities, bumps, and vibrations. This movement is essential for providing a comfortable ride, maintaining tire contact with the road surface, and improving overall handling and stability. The differential gears must accommodate this wheel movement without hindering power transmission. They are mounted within the axle housing, which is connected to the suspension system, allowing the wheels to move up and down while maintaining their connection to the differential assembly.

- Drive Axle and Halfshafts: In many vehicles, the differential gears are located within the drive axle assembly, which is an integral part of the suspension system. The drive axle assembly consists of the differential gears, axle housing, and halfshafts (also known as axle shafts). The halfshafts connect the differential gears to the wheel hubs, transmitting power from the differential to the wheels. The suspension system and differential gears work in conjunction to allow the halfshafts to flex and accommodate the vertical movement of the wheels while maintaining power delivery.

- Torque Steer: Differential gears can also influence torque steer, which is the tendency of the vehicle to pull to one side during acceleration. Torque steer occurs when one wheel receives more torque than the other, causing an imbalance in power delivery and resulting in steering effects. Differential gears, particularly in front-wheel-drive vehicles, help manage torque steer by distributing torque between the front wheels. Advanced differential technologies, such as limited-slip differentials or electronic torque vectoring systems, can further mitigate torque steer and enhance overall vehicle stability.

- Performance Applications: In high-performance or sport-oriented vehicles, the interaction between differential gears and the suspension system becomes even more critical. The suspension system is usually designed to provide optimal handling characteristics, including minimal body roll, precise cornering, and responsive feedback. Differential gears, particularly limited-slip differentials or electronically controlled differentials, can be specifically tuned to complement the suspension system and maximize traction, stability, and cornering performance. This integration ensures that the power delivered to the wheels is effectively utilized, enhancing the vehicle’s overall dynamic capabilities.

In summary, differential gears interact with the suspension system of a vehicle by accommodating wheel movement, transmitting power while allowing independent wheel motion, connecting to the drive axle and halfshafts, managing torque steer, and optimizing performance in high-performance applications. This interaction ensures smooth power transmission, proper handling, stability, and overall vehicle performance.

How does a limited-slip differential differ from an open differential?

A limited-slip differential (LSD) differs from an open differential in several key ways. Here’s a detailed explanation:

1. Torque Distribution:

In an open differential, torque is distributed equally between the two wheels. When both wheels have good traction, this distribution works well. However, if one wheel loses traction, the open differential will send more power to that wheel, causing it to spin while the other wheel receives minimal power. This can result in reduced traction and compromised performance.

In contrast, a limited-slip differential actively biases torque distribution. It uses various mechanisms, such as clutch packs, viscous fluids, or gear arrangements, to transfer more torque to the wheel with better traction. This torque biasing helps improve traction and power delivery, especially in situations where one wheel has reduced traction. By providing a more balanced torque distribution, a limited-slip differential enhances overall performance and stability.

2. Traction Improvement:

One of the primary advantages of a limited-slip differential is its ability to improve traction compared to an open differential. When one wheel encounters reduced traction, such as on slippery surfaces or during cornering, the limited-slip differential transfers more torque to the wheel with better traction. This helps maximize the vehicle’s ability to maintain forward motion and improves overall stability by minimizing wheel slip. In contrast, an open differential may distribute power to the wheel with the least resistance, resulting in reduced traction and compromised handling.

3. Drivability:

In terms of drivability, open differentials are generally smoother and more predictable. They allow the wheels to rotate at different speeds during turns, facilitating smooth operation and minimizing binding or tire scrubbing. Open differentials are also less expensive to manufacture, making them a common choice for everyday vehicles.

On the other hand, limited-slip differentials offer improved drivability compared to open differentials, especially in situations with varying traction conditions. Limited-slip differentials strike a balance between improved traction and maintaining drivability for everyday use. They can provide better control and stability during acceleration, cornering, and challenging road conditions.

4. Performance and Handling:

Limited-slip differentials are often favored in performance-oriented vehicles or applications that require enhanced handling characteristics. The ability to transfer torque to the wheel with better traction helps optimize power delivery, reduce wheel slip, and improve overall performance. Limited-slip differentials can enhance cornering ability, stability, and agility, allowing drivers to navigate curves and corners with more confidence and control.

In contrast, open differentials may be more prone to wheel slip, particularly in high-performance or demanding driving situations. This can result in compromised performance and reduced stability.

In summary, a limited-slip differential differs from an open differential in terms of torque distribution, traction improvement, drivability, and performance. By actively biasing torque distribution and improving traction, a limited-slip differential offers better performance and handling characteristics, especially in challenging driving conditions.

editor by Dream 2024-05-08