Product Description

Product Description

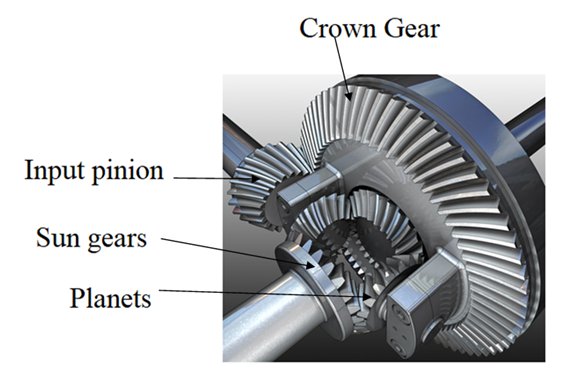

| Features | Function | Transmits power from differential to wheels |

| Teeth Count | 16 Teeth | |

| Compatibility | Designed for cargo tricycles, fits differential system | |

| Material | Durable and high-quality material | |

| Advantages | Efficient power distribution, enhances traction |

For additional information and models, kindly get in touch with the supplier.

Company Profile

ZheJiang Kalida Industry Co., Ltd., established in 2008, is a reputable exporter of OEM motorcycle parts with over 15 years of experience.

We boast over 1,000 top-tier parts suppliers, backed by a team of 50 professionals, and a spacious 4,000m2 warehouse in ZheJiang . Our partnered suppliers manufacture parts for renowned motorcycle manufacturers in China.

We perceive ourselves as a crucial intermediary connecting China’s top-class parts factories with global importers. Much like our customers’ China Office, we assist them in handling all aspects related to China: product recommendations, quality control, cost management, packaging design, documentation, shipping, and more.

We are dedicated to providing our professional services to global importers who value professionalism, integrity, and a strong reputation. If you are interested, please don’t hesitate to contact us, and let’s initiate a long-term, mutually beneficial business cooperation.

Inspection

Packaging & Shipping

Exhibition

| After-sales Service: | Yes |

|---|---|

| Warranty: | Yes |

| Type: | Motorcycle Body Parts |

| Certification: | ISO9001: 2000, CCC, CE |

| Material: | Alloy |

| Product No.: | 01003824 |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you maintain and service a differential gear?

Maintaining and servicing a differential gear is crucial to ensure its optimal performance and longevity. Here’s a detailed explanation of the maintenance and servicing process:

1. Regular Inspection:

Perform regular visual inspections of the differential gear to check for any signs of damage, leaks, or excessive wear. Look for oil leaks around the differential housing and inspect the driveshaft, axles, and seals for any signs of damage or leakage. Additionally, listen for any abnormal noises coming from the differential during operation, as they may indicate underlying issues.

2. Fluid Change:

Regularly change the differential fluid as recommended by the vehicle manufacturer. Over time, the fluid can become contaminated with debris, moisture, and metal particles, which can cause accelerated wear and reduced performance. Changing the fluid helps maintain proper lubrication and cooling of the differential gears. Refer to the vehicle’s owner manual or service guide for the recommended fluid type and change intervals.

3. Fluid Level Check:

Check the fluid level in the differential regularly to ensure it is within the recommended range. Use the appropriate method specified by the vehicle manufacturer to check the fluid level, such as a dipstick or inspection plug. Maintaining the correct fluid level is essential for proper lubrication and cooling of the gears.

4. Seal Replacement:

If you notice any leaks or damaged seals, it is important to replace them promptly. Leaking seals can lead to fluid loss, which can cause inadequate lubrication and potential damage to the differential gears. Replace seals as per the manufacturer’s recommendations and ensure proper installation to prevent future leaks.

5. Gear Inspection and Adjustment:

Periodically inspect the gears for signs of wear, damage, or misalignment. If any issues are detected, consult a qualified technician or mechanic for further evaluation and adjustment. Gears that are excessively worn or damaged may need to be replaced to maintain the proper functioning of the differential.

6. Service Differential Components:

Some differential systems have additional components that require servicing. For example, limited-slip differentials may have clutch packs or friction plates that need periodic inspection and maintenance. Follow the manufacturer’s guidelines for servicing these components, which may involve cleaning, lubrication, or replacement as necessary.

7. Professional Servicing:

In addition to regular maintenance tasks, it is recommended to have the differential gear serviced by a professional technician or mechanic at specific intervals or when experiencing significant issues. Professional servicing may involve more in-depth inspections, adjustments, or repairs that require specialized tools and knowledge.

8. Follow Manufacturer Recommendations:

Always refer to the vehicle manufacturer’s recommendations and guidelines for maintaining and servicing the differential gear. They provide specific instructions tailored to your vehicle’s make, model, and differential type, ensuring that you follow the appropriate procedures for optimal performance and longevity.

In summary, maintaining and servicing a differential gear involves regular inspections, fluid changes, fluid level checks, seal replacements, gear inspections and adjustments, servicing of differential components, professional servicing when necessary, and adherence to manufacturer recommendations. By following these steps, you can help ensure the proper functioning and durability of the differential gear in your vehicle.

Can differential gears be upgraded or customized for specific applications?

Yes, differential gears can be upgraded or customized for specific applications to enhance performance, traction, and handling. Here’s a detailed explanation of how differential gears can be upgraded or customized:

- Gear Ratio Changes: One way to customize differential gears is by changing the gear ratios. Different gear ratios can alter the torque distribution between the wheels, optimizing it for specific applications. For example, shorter gear ratios can improve acceleration and low-end torque, while taller gear ratios can enhance fuel efficiency and top speed. Gear ratio changes are commonly performed in performance vehicles, off-road vehicles, and racing applications to suit specific driving requirements.

- Limited-Slip Differentials (LSD): Upgrading to limited-slip differentials can significantly improve traction and handling. LSDs distribute torque between the wheels more evenly compared to open differentials, reducing wheel spin and maximizing grip. LSDs are particularly beneficial in high-performance vehicles, off-road vehicles, and applications where maintaining traction is crucial, such as racing or challenging driving conditions. LSDs can be retrofitted or factory-installed depending on the vehicle and its specific requirements.

- Electronic Differential Controls: Some vehicles feature electronic controls for the differential system. These controls allow customization of the differential’s behavior based on driving conditions and driver preferences. Through electronic controls, differential characteristics such as torque distribution, responsiveness, and traction management can be adjusted. This customization helps optimize performance, stability, and traction in various driving scenarios.

- Aftermarket Upgrades: The aftermarket industry offers various differential upgrade options. These include performance differentials, heavy-duty differentials, and specialized differentials designed for specific applications. These aftermarket upgrades can provide improved durability, enhanced traction, and higher torque capacity compared to stock differentials. They are commonly chosen by enthusiasts, off-road enthusiasts, and individuals seeking to enhance the capabilities of their vehicles for specific purposes.

- Custom Differential Designs: In certain cases, custom differential designs can be developed to meet specific application requirements. For example, in motorsports, differential designs can be tailored to optimize performance, handling, and traction for the specific demands of the racing discipline. Custom differentials may involve unique gear arrangements, specialized materials, and advanced features to deliver superior performance in targeted applications.

In summary, differential gears can be upgraded or customized to suit specific applications. Upgrades may include gear ratio changes, installation of limited-slip differentials, utilization of electronic differential controls, aftermarket differential options, or even custom differential designs. These modifications and customizations allow for improved performance, traction, and handling, catering to the specific needs and preferences of different vehicles and driving scenarios.

What are the applications of differential gears in off-road vehicles?

Off-road vehicles rely on differential gears for various applications that enhance their performance and capability in challenging terrains. Here’s a detailed explanation:

1. Traction Improvement:

One of the primary applications of differential gears in off-road vehicles is to improve traction. Off-road terrain often consists of uneven surfaces, loose soil, rocks, mud, or deep snow, which can cause the wheels to lose traction. Differential gears, such as limited-slip differentials or locking differentials, help distribute torque to the wheels with better traction, reducing wheel slip and maximizing grip. This allows off-road vehicles to maintain forward momentum and conquer obstacles that would otherwise be difficult to navigate.

2. All-Wheel Drive (AWD) Systems:

Off-road vehicles commonly utilize differential gears in their all-wheel drive (AWD) systems. AWD systems distribute power to all four wheels, providing better traction and stability on off-road terrain. Differential gears enable power transfer between the front and rear axles, as well as between the left and right wheels on each axle, allowing for optimal torque distribution based on traction conditions. This helps improve overall off-road performance and control.

3. Articulation and Wheel Independence:

Off-road vehicles often encounter uneven terrain with varying degrees of wheel articulation. Differential gears play a crucial role in maintaining wheel independence, allowing each wheel to move up or down independently to better conform to the terrain. This ensures that the wheels maintain contact with the ground and enhances traction, especially when navigating over rocks, logs, or steep inclines.

4. Hill Climbing and Descending:

When climbing steep inclines or descending steep slopes, differential gears are essential for off-road vehicles. In these situations, differential gears help distribute torque between the wheels on each axle, allowing the wheels with better traction to propel the vehicle forward or provide controlled braking. This improves stability, prevents wheel slip, and enhances the vehicle’s ability to tackle challenging uphill or downhill sections.

5. Off-Road Racing:

In off-road racing, differential gears are utilized to optimize performance and handling. High-performance off-road vehicles often employ advanced differential systems, such as limited-slip differentials or torque vectoring differentials. These systems actively distribute torque to the wheels with better traction, improving acceleration, cornering ability, and overall vehicle dynamics in competitive off-road racing environments.

6. Rock Crawling and Trail Driving:

Off-road vehicles designed for rock crawling or trail driving heavily rely on differential gears. These vehicles require precise control and maximum traction in low-speed, technical situations. Differential gears, particularly locking differentials, are employed to ensure that both wheels on an axle rotate together, maximizing traction and allowing the vehicle to maneuver over challenging obstacles, such as large rocks, boulders, or deep ruts.

In summary, differential gears in off-road vehicles have several applications, including traction improvement, all-wheel drive systems, articulation and wheel independence, hill climbing and descending, off-road racing, rock crawling, and trail driving. These applications enhance the performance, control, and capability of off-road vehicles in demanding and rugged terrains.

editor by CX 2023-10-17