Product Description

Pinion Rack Round Worm Screw Helical Hypoid Straight Ring Spiral Forged Bevel Spur Differential Steering Internal Box Spline Plastic Nylon Stainless Steel Gear

Gears:

The processing production line we see can produce the following gears: spur gears, helical gears, bevel gears, spiral bevel gears, straight bevel gears, internal gears, worm gears, gear rack

| Process | CNC machining,CNC milling, cnc lathe machining |

| Available Material | 1.Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420,etc. |

| 2.Steel: C45, 40Cr, 42CrMo, 20CrNiMo, 20CrMnTi, etc. (AISI 1045, 5140, 4140/4142, 8620 etc.) | |

| 3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200CuZn37), C28000(CuZn40),etc. | |

| 4.Bronze: C51000, C52100, C54400, etc. | |

| 5. Iron: 1213, 12L14,1215,etc. | |

| 6. Aluminum: Al6061, Al6063,Al2571,Al7075 etc | |

| 7. Carbon steel:AISI1006,AISI1571,AISI1571,etc. | |

| 8.Nylon PA66,MC901,POM plastic ects | |

| Hardness | HRC50~55 |

| Quality Control | ISO9001 and ISO14001 |

| Dimension bore tolerances | -/+0.01mm |

| Quality standard | AGMA, JIS, DIN |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized |

| Surface treatment | black oxide,Zn-plated,ni-plated,tin-plated,chrome plated,passivated,sandblast and anodize,chromate,polish,electro painting,black anodize,plain,H.D.G,etc. |

| Dimensions Tolerance | ±0.01mm or more precise |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. |

We also have injection molding machines, which can produce plastic nylon gears according to your needs

Related products

Transmission products:

Gearbox/gear reducer:

Click here for more details!

Customization process

Support Customized Gears from Customers’ drawings and samples and Various non-standard customization

1.Products Discussions

Customers send drawings oramples, and quote according to customers’ requirements.

2.Molds designing

Designing 3D drawings and optimizing the products.

3.Drawing confirmation

Sending the mold drawing tothe customers , and the customers CHINAMFG for confirmation.

4.Molds Construction

Manufacture molds accurately and accurately according to the drawings.

5.Moulds Inspection and Moulds Test

Detect various indicators of molds and optimization of inner cavities.

6.Sample Aprroval from Customer

Customers approve the samples and confirm them for bulk production.

7.Mass Production

Bulk production according to customers’s PO

8.PO Finished

Shipping to the customer andthe customers receive the gears.

If you need other customized requirements, please click here to contact us!

Why Choose Us

We enthusiastically provide sincere and prompt service to our customers and establish sustainable business relationship with them.

100% Factory inspection, we are responsible for any problems subjected to malfunction in warranty period.

We Can Provide You:

- On-time Delivery with More Choice

- Product Solutions and Service

- Long Quality Guarantee

- Local Technical Support

- Fast Response to Customers’ Feedbacks in 24 hours

Also I would like to take this opportunity to give a brief introduction of our CHINAMFG company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

You also can check our website to know for more details, if you need our products catalogue, please contact with us.

Company information

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Cast Iron |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

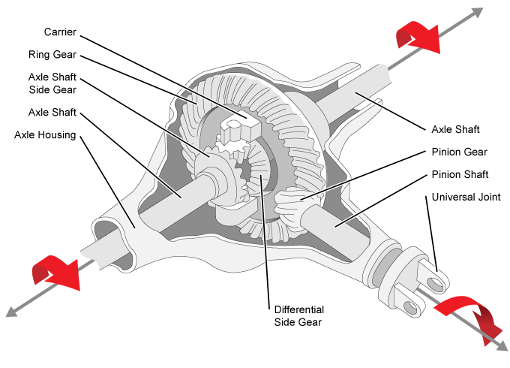

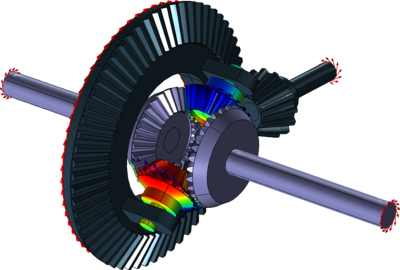

How do you address noise and vibration issues in a differential gear system?

Noise and vibration issues in a differential gear system can be concerning and may indicate underlying problems. Here are several steps that can be taken to address these issues:

- 1. Inspection: Begin by visually inspecting the differential gear system for any visible signs of damage, leaks, or loose components. Check the differential housing, seals, and related components for any abnormalities. This can help identify any obvious issues that may be causing the noise or vibration.

- 2. Fluid Check: Ensure that the differential gear system has the proper amount of fluid and that the fluid is in good condition. Low or contaminated fluid can contribute to noise and vibration problems. If necessary, drain and replace the differential fluid following the manufacturer’s recommendations.

- 3. Lubrication: Proper lubrication is essential for smooth operation of the differential gears. If the noise or vibration issues persist, consider applying a high-quality gear lubricant recommended by the vehicle manufacturer. Ensure that the lubricant meets the required specifications.

- 4. Tightening and Adjustment: Check for any loose fasteners or components in the differential gear system. Tighten any bolts or nuts that may have come loose. Additionally, verify that the differential gears are properly adjusted and aligned. Incorrect gear meshing or misalignment can cause noise and vibration problems.

- 5. Bearing Inspection and Replacement: Worn or damaged bearings can contribute to noise and vibration. Inspect the differential bearings for signs of wear, pitting, or excessive play. If any issues are detected, replace the faulty bearings with new ones of the appropriate size and specification.

- 6. Gear Replacement: If the differential gears themselves are worn, chipped, or damaged, they may need to be replaced. Gears with significant wear or damage can cause noise and vibration. Consult a professional mechanic or technician for an accurate assessment and to determine if gear replacement is necessary.

- 7. Seals Replacement: Damaged or worn seals can allow contaminants to enter the differential gear system, leading to noise and vibration. Replace any faulty seals to ensure a proper seal and prevent fluid leaks.

- 8. Professional Diagnosis: If the noise and vibration issues persist despite these measures, it is advisable to seek assistance from a qualified mechanic or technician. They have the expertise and specialized tools to diagnose complex differential gear problems accurately. They may perform additional tests, such as a gear backlash measurement or a comprehensive inspection of the gears and bearings, to identify the source of the issues.

It’s important to address noise and vibration issues in a differential gear system promptly to prevent further damage and ensure safe and smooth vehicle operation. Regular maintenance, including fluid checks and gear inspections, can help detect potential problems early and prevent more significant issues from arising.

How do differential gears contribute to traction in slippery conditions?

In slippery conditions, such as driving on ice, snow, or wet surfaces, differential gears play a crucial role in improving traction and maintaining vehicle control. Here’s a detailed explanation of how differential gears contribute to traction in slippery conditions:

- Torque Distribution: Differential gears allow torque to be distributed between the wheels on the same axle. In slippery conditions, where traction is reduced, differential gears enable power to be sent to the wheels with better grip. This distribution of torque helps maximize traction and prevent wheel spin.

- Wheel Speed Variation: In slippery conditions, the wheels on the same axle may encounter different levels of traction. For example, one wheel might be on a patch of ice while the other is on a surface with better grip. Differential gears accommodate this variation by allowing the wheels to rotate at different speeds. This wheel speed variation helps ensure that power is directed to the wheels with more traction, improving overall grip and stability.

- Slip Limitation: When one wheel loses traction and starts to slip, the other wheel with better grip can potentially receive less power due to the default behavior of an open differential. However, some differential systems employ advanced features like limited-slip differentials (LSD) or electronic traction control systems. These systems detect wheel slip and apply mechanisms to limit slip and redirect power to the wheel with better traction, effectively improving traction in slippery conditions.

- Positive Traction Devices: In some cases, differential gears can be equipped with positive traction devices such as locking differentials or electronic locking differentials. These devices lock the differential gears, forcing both wheels on the same axle to rotate at the same speed. This feature is particularly beneficial in extremely slippery conditions where maximum traction is essential. By locking the differential, these devices ensure that power is evenly distributed to both wheels, maximizing grip and traction.

- Off-Road Capability: Differential gears with advanced features like limited-slip differentials or locking differentials are commonly employed in off-road vehicles. These vehicles often encounter challenging terrain with low-traction conditions. The differential systems in these vehicles enhance off-road capability by transferring power to the wheels with the most traction, preventing wheel spin, and allowing the vehicle to navigate through difficult terrain more effectively.

In summary, differential gears contribute to traction in slippery conditions by distributing torque between wheels, accommodating wheel speed variation, limiting slip through advanced features, and offering positive traction devices. These mechanisms allow power to be directed to the wheels with better grip, improving traction, stability, and overall vehicle control in slippery conditions.

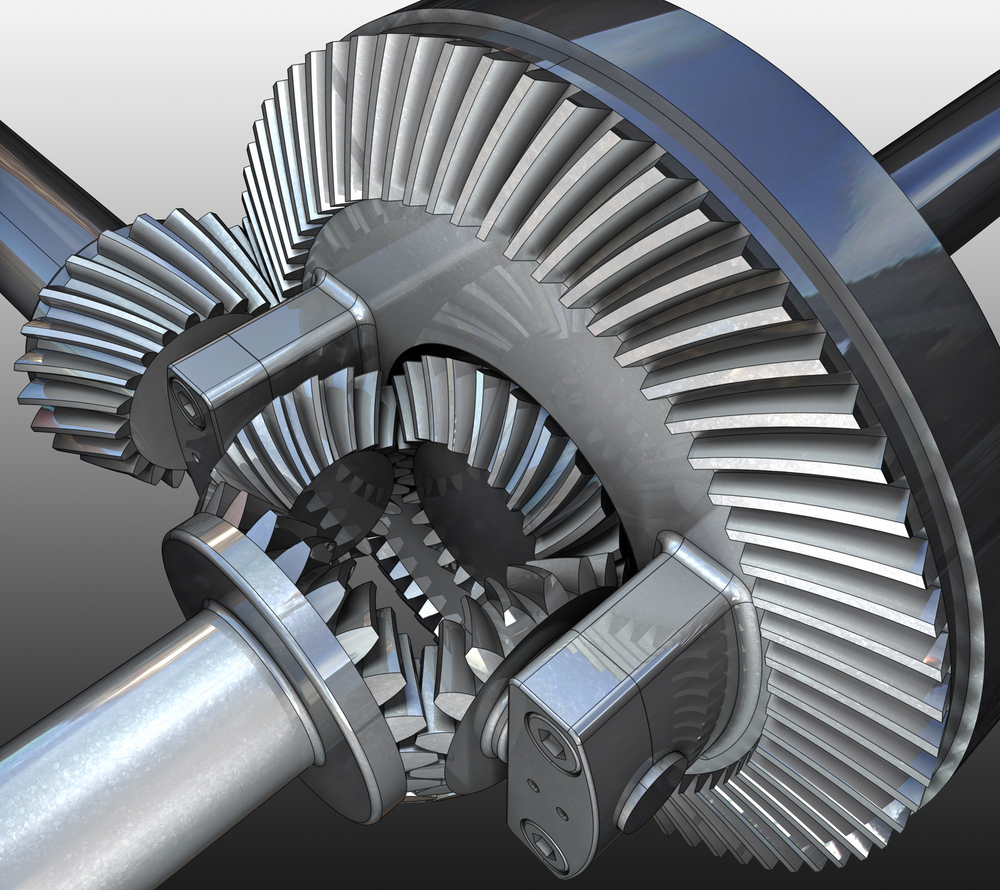

What are the functions of a differential gear in a vehicle?

A differential gear in a vehicle serves several important functions. Here’s a detailed explanation:

1. Torque Distribution:

One of the primary functions of a differential gear is to distribute torque (rotational force) from the engine to the wheels. As the engine generates power, the differential ensures that it is transmitted to the wheels efficiently and effectively. By dividing the torque between the two wheels, the differential enables both wheels to receive power and propel the vehicle forward.

2. Differential Action:

The differential gear allows the wheels to rotate at different speeds when the vehicle is turning or when one wheel encounters different traction conditions. This differential action is crucial for smooth and controlled maneuvering. By enabling the outer wheel to rotate faster than the inner wheel during a turn, the differential allows the vehicle to negotiate corners without binding or skidding.

3. Wheel Speed Compensation:

When the vehicle is turning, the inside wheel travels a shorter distance compared to the outside wheel. Without a differential, this speed difference would cause significant drivetrain stress and tire wear. The differential gear compensates for the varying wheel speeds by allowing the wheels to rotate at different speeds, ensuring smooth operation and minimizing strain on the drivetrain components.

4. Traction Improvement:

In situations where one wheel loses traction, such as when driving on slippery surfaces or uneven terrain, the differential gear helps improve traction. By allowing the wheel with traction to receive more power, the differential ensures that the vehicle can continue moving forward. This is particularly important in vehicles with two-wheel drive, as the differential helps optimize power delivery to the wheel with better traction.

5. Reducing Tire Wear:

The differential gear contributes to reducing tire wear by accommodating differences in wheel speeds. By allowing the wheels to rotate at different speeds during turns, the differential minimizes tire scrubbing and uneven wear. It helps distribute the forces evenly across the tires, promoting longer tire life and maintaining better overall traction.

6. Enhanced Stability and Handling:

The differential gear plays a crucial role in enhancing vehicle stability and handling. By allowing the wheels to rotate independently, the differential facilitates better control during turns and maneuvering. It helps maintain proper weight distribution, prevents excessive understeer or oversteer, and promotes balanced handling characteristics.

Overall, the differential gear is an integral component of a vehicle’s drivetrain, responsible for torque distribution, wheel speed compensation, traction improvement, reducing tire wear, and enhancing stability and handling. It enables smooth and efficient power delivery to the wheels while accommodating varying speed and traction conditions, resulting in improved performance and driving dynamics.

editor by CX 2023-09-22