Product Description

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

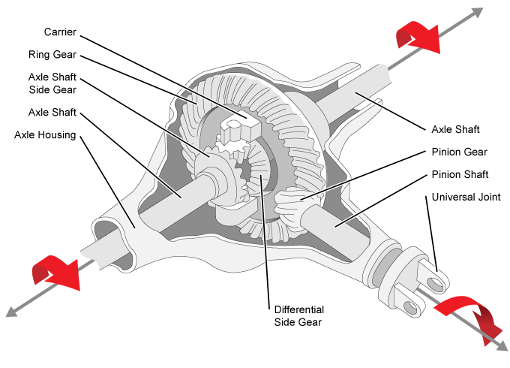

What are the symptoms of a failing differential gear?

A failing or faulty differential gear can exhibit various symptoms that indicate potential problems with its operation. Here are some common signs to look out for:

- 1. Whining or Howling Noises: A prominent symptom of a failing differential gear is the presence of whining, howling, or rumbling noises coming from the rear of the vehicle. These noises may increase with vehicle speed or during specific driving maneuvers, such as turning or accelerating. The noises can indicate worn or damaged gears, insufficient lubrication, or misalignment within the differential assembly.

- 2. Clunking or Clicking Sounds: Another symptom of a failing differential gear is the occurrence of clunking or clicking sounds, particularly during changes in direction or when shifting between drive modes. This can indicate worn or damaged gears, worn universal joints, or loose components within the differential.

- 3. Vibration or Shuddering: A failing differential gear may cause vibration or shuddering sensations, especially when accelerating or decelerating. This can be a result of worn or damaged gears, improper gear meshing, or worn bearings within the differential assembly.

- 4. Difficulty in Turning: If the differential gear is experiencing issues, you may notice increased difficulty in turning the vehicle, particularly during sharp turns or low-speed maneuvers. This can be caused by uneven torque distribution or limited mobility of the differential gears.

- 5. Fluid Leaks: Leaking fluid around the differential housing is a potential indicator of a failing gear. Differential fluid is essential for lubrication and cooling of the gears and bearings. A leak can result from worn seals, cracked housing, or damaged components within the differential assembly.

- 6. Excessive Tire Wear: A failing differential gear may lead to uneven tire wear. If you notice significant wear on the inner or outer edges of the tires, it could be a sign of differential problems. Uneven torque distribution can cause increased stress on specific tires, leading to abnormal wear patterns.

- 7. Gear Slippage: In severe cases, a failing differential gear may result in gear slippage. This means that power is not being effectively transferred to the wheels, causing a loss of traction and reduced vehicle performance. Gear slippage can occur due to worn or damaged gears, insufficient lubrication, or other internal failures within the differential.

If you observe any of these symptoms, it is recommended to have your vehicle inspected by a qualified mechanic or technician. They can diagnose the exact cause of the issues and determine if the differential gear requires repair or replacement.

How do differential gears contribute to traction in slippery conditions?

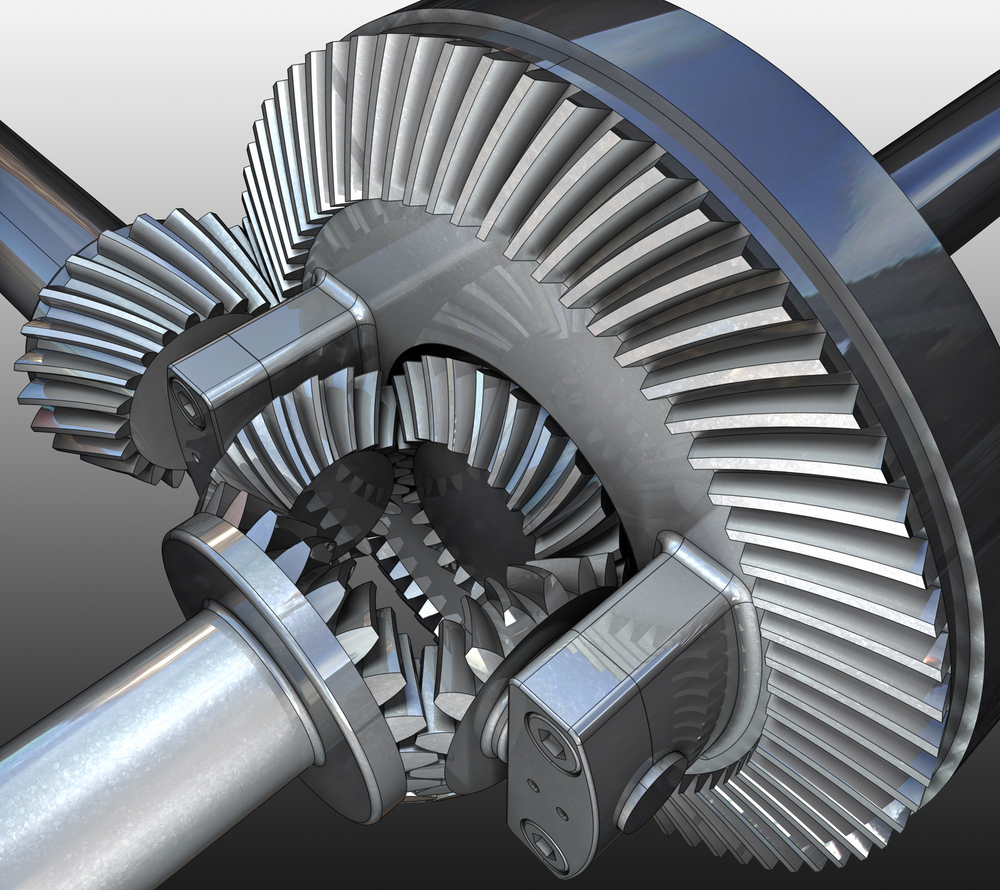

In slippery conditions, such as driving on ice, snow, or wet surfaces, differential gears play a crucial role in improving traction and maintaining vehicle control. Here’s a detailed explanation of how differential gears contribute to traction in slippery conditions:

- Torque Distribution: Differential gears allow torque to be distributed between the wheels on the same axle. In slippery conditions, where traction is reduced, differential gears enable power to be sent to the wheels with better grip. This distribution of torque helps maximize traction and prevent wheel spin.

- Wheel Speed Variation: In slippery conditions, the wheels on the same axle may encounter different levels of traction. For example, one wheel might be on a patch of ice while the other is on a surface with better grip. Differential gears accommodate this variation by allowing the wheels to rotate at different speeds. This wheel speed variation helps ensure that power is directed to the wheels with more traction, improving overall grip and stability.

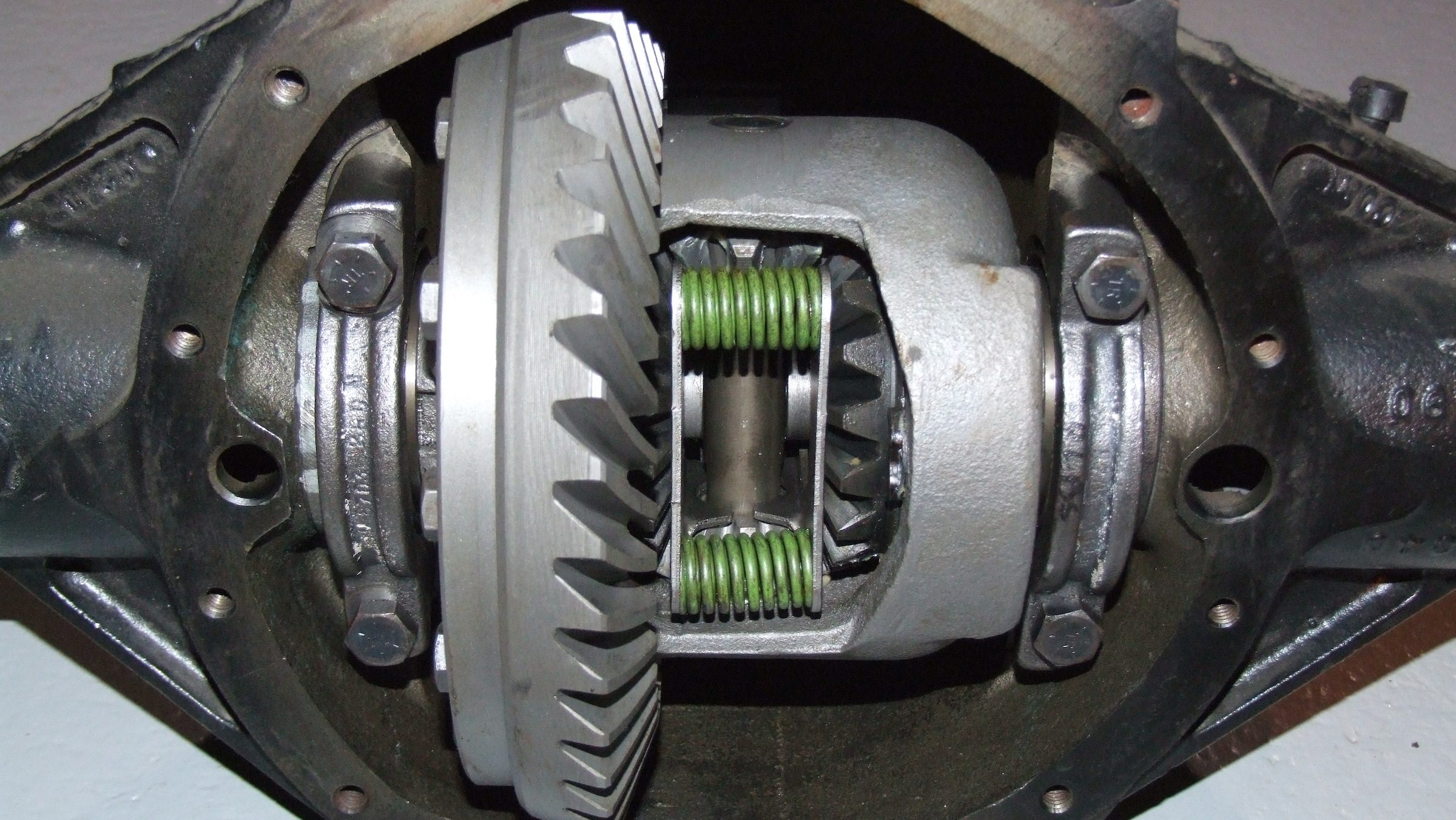

- Slip Limitation: When one wheel loses traction and starts to slip, the other wheel with better grip can potentially receive less power due to the default behavior of an open differential. However, some differential systems employ advanced features like limited-slip differentials (LSD) or electronic traction control systems. These systems detect wheel slip and apply mechanisms to limit slip and redirect power to the wheel with better traction, effectively improving traction in slippery conditions.

- Positive Traction Devices: In some cases, differential gears can be equipped with positive traction devices such as locking differentials or electronic locking differentials. These devices lock the differential gears, forcing both wheels on the same axle to rotate at the same speed. This feature is particularly beneficial in extremely slippery conditions where maximum traction is essential. By locking the differential, these devices ensure that power is evenly distributed to both wheels, maximizing grip and traction.

- Off-Road Capability: Differential gears with advanced features like limited-slip differentials or locking differentials are commonly employed in off-road vehicles. These vehicles often encounter challenging terrain with low-traction conditions. The differential systems in these vehicles enhance off-road capability by transferring power to the wheels with the most traction, preventing wheel spin, and allowing the vehicle to navigate through difficult terrain more effectively.

In summary, differential gears contribute to traction in slippery conditions by distributing torque between wheels, accommodating wheel speed variation, limiting slip through advanced features, and offering positive traction devices. These mechanisms allow power to be directed to the wheels with better grip, improving traction, stability, and overall vehicle control in slippery conditions.

How does a limited-slip differential differ from an open differential?

A limited-slip differential (LSD) differs from an open differential in several key ways. Here’s a detailed explanation:

1. Torque Distribution:

In an open differential, torque is distributed equally between the two wheels. When both wheels have good traction, this distribution works well. However, if one wheel loses traction, the open differential will send more power to that wheel, causing it to spin while the other wheel receives minimal power. This can result in reduced traction and compromised performance.

In contrast, a limited-slip differential actively biases torque distribution. It uses various mechanisms, such as clutch packs, viscous fluids, or gear arrangements, to transfer more torque to the wheel with better traction. This torque biasing helps improve traction and power delivery, especially in situations where one wheel has reduced traction. By providing a more balanced torque distribution, a limited-slip differential enhances overall performance and stability.

2. Traction Improvement:

One of the primary advantages of a limited-slip differential is its ability to improve traction compared to an open differential. When one wheel encounters reduced traction, such as on slippery surfaces or during cornering, the limited-slip differential transfers more torque to the wheel with better traction. This helps maximize the vehicle’s ability to maintain forward motion and improves overall stability by minimizing wheel slip. In contrast, an open differential may distribute power to the wheel with the least resistance, resulting in reduced traction and compromised handling.

3. Drivability:

In terms of drivability, open differentials are generally smoother and more predictable. They allow the wheels to rotate at different speeds during turns, facilitating smooth operation and minimizing binding or tire scrubbing. Open differentials are also less expensive to manufacture, making them a common choice for everyday vehicles.

On the other hand, limited-slip differentials offer improved drivability compared to open differentials, especially in situations with varying traction conditions. Limited-slip differentials strike a balance between improved traction and maintaining drivability for everyday use. They can provide better control and stability during acceleration, cornering, and challenging road conditions.

4. Performance and Handling:

Limited-slip differentials are often favored in performance-oriented vehicles or applications that require enhanced handling characteristics. The ability to transfer torque to the wheel with better traction helps optimize power delivery, reduce wheel slip, and improve overall performance. Limited-slip differentials can enhance cornering ability, stability, and agility, allowing drivers to navigate curves and corners with more confidence and control.

In contrast, open differentials may be more prone to wheel slip, particularly in high-performance or demanding driving situations. This can result in compromised performance and reduced stability.

In summary, a limited-slip differential differs from an open differential in terms of torque distribution, traction improvement, drivability, and performance. By actively biasing torque distribution and improving traction, a limited-slip differential offers better performance and handling characteristics, especially in challenging driving conditions.

editor by CX 2024-04-03