Product Description

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

| Application: | Motor, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

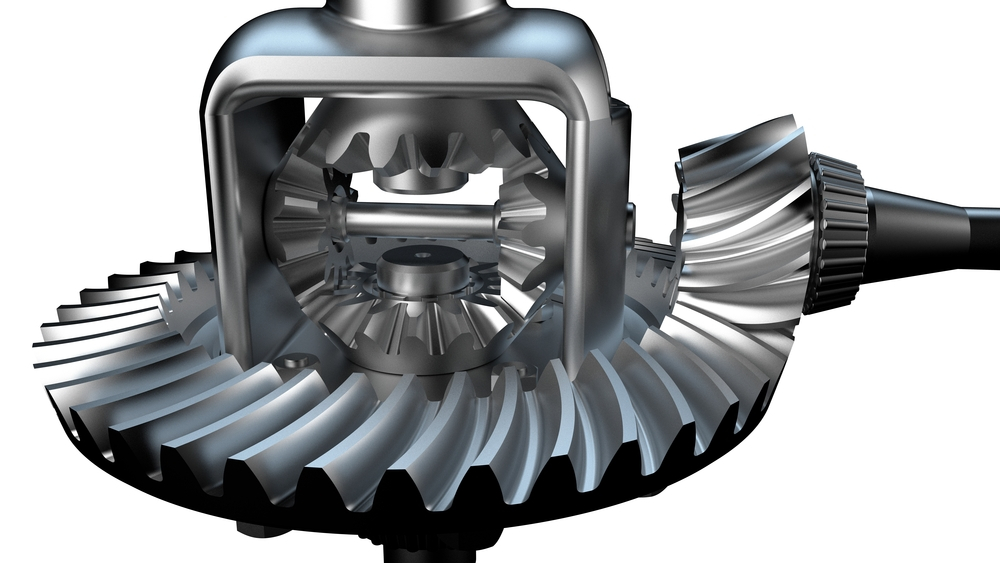

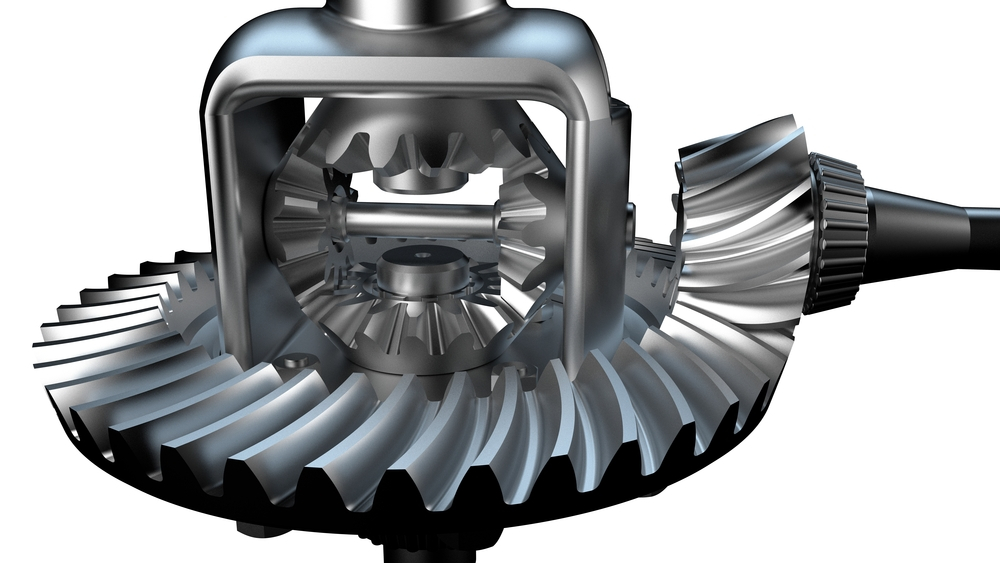

How does a differential gear distribute power between the wheels?

A differential gear is responsible for distributing power between the wheels of a vehicle, allowing them to rotate at different speeds while maintaining torque transfer. Here’s a detailed explanation of how a differential gear accomplishes this:

1. Power Input:

The differential gear receives power from the transmission or driveshaft connected to the engine. This power is transmitted to the differential assembly, which is typically located in the axle housing.

2. Ring and Pinion Gears:

Within the differential assembly, the power from the driveshaft is transferred to the ring and pinion gears. The ring gear is a large gear that surrounds the differential assembly, while the pinion gear is a smaller gear connected to the driveshaft. The interaction between these gears allows the power to be redirected.

3. Side Gears and Spider Gears:

The ring gear is connected to side gears, also known as bevel gears, through a set of small gears called spider gears. The side gears are attached to the axle shafts, which are responsible for transmitting power to the wheels. The spider gears allow the side gears to rotate independently of each other while maintaining torque transfer.

4. Differential Action:

As the vehicle moves, the differential gears enable the wheels to rotate at different speeds during turns. When the vehicle is moving in a straight line, the spider gears rotate smoothly, allowing equal power distribution to both wheels. However, during a turn, the inside wheel travels a shorter distance than the outside wheel, causing them to rotate at different speeds.

5. Speed and Torque Distribution:

The differential gear adjusts the speed and torque distribution between the wheels based on their rotational differences. When the vehicle is turning, the spider gears allow one wheel to rotate faster than the other, ensuring that torque is transferred to the wheel with better traction. This allows the wheels to rotate at different speeds, preventing tire scrubbing and providing smooth cornering.

6. Limited-Slip and Locking Differentials:

In certain differential systems, such as limited-slip differentials or locking differentials, additional mechanisms are incorporated to enhance traction and power distribution. Limited-slip differentials use clutch packs or friction plates to provide a predetermined amount of resistance, allowing some speed differentiation between the wheels while still transferring power. Locking differentials, on the other hand, lock the side gears together, ensuring equal torque distribution to both wheels, regardless of traction conditions.

7. Differential Types:

There are various types of differentials, including open differentials, limited-slip differentials, electronic differentials, torque vectoring differentials, and more. Each type has its own mechanisms and technologies to distribute power between the wheels effectively, depending on the vehicle’s requirements and driving conditions.

In summary, a differential gear distributes power between the wheels by utilizing a system of gears, including ring and pinion gears, side gears, and spider gears. The differential action allows the wheels to rotate at different speeds during turns, ensuring smooth cornering and preventing tire scrubbing. Additional mechanisms, such as limited-slip or locking differentials, can further enhance traction and power distribution in various driving conditions.

How do differential gears affect fuel efficiency in vehicles?

In vehicles, differential gears can have an impact on fuel efficiency. Here’s a detailed explanation of how differential gears affect fuel efficiency:

- Gear Ratio: The gear ratio of the differential can affect fuel efficiency. A higher gear ratio (numerically lower) allows the engine to run at lower RPMs for a given speed, which can result in improved fuel efficiency. This is because the engine operates more efficiently in its lower RPM range, consuming less fuel. On the other hand, a lower gear ratio (numerically higher) can provide better acceleration and performance but may result in higher fuel consumption.

- Friction and Efficiency Losses: Differential gears introduce friction and mechanical losses in the drivetrain. As power is transmitted from the engine to the wheels through the differential, some energy is lost due to friction in the gears, bearings, and other components. These frictional losses reduce overall efficiency and can have a slight impact on fuel consumption. However, modern differentials are designed with efficiency in mind, and advancements in lubrication, materials, and manufacturing techniques help minimize these losses.

- Limited-Slip Differentials (LSD): Limited-slip differentials (LSDs) can have a minor effect on fuel efficiency compared to open differentials. LSDs use additional mechanisms to distribute torque between wheels, resulting in a slight increase in mechanical losses and energy consumption. However, the impact on fuel efficiency is generally minimal and may not be noticeable in everyday driving situations.

- Driving Style and Traction: The traction characteristics of differential gears can indirectly influence fuel efficiency. In slippery conditions or situations where wheelspin occurs, open differentials may allow excessive power to be lost in wheel slip, resulting in reduced traction and poorer fuel efficiency. Limited-slip differentials or advanced traction control systems can minimize wheel slip and improve overall traction, leading to better fuel efficiency by reducing power wastage.

- Vehicle Type and Design: The impact of differential gears on fuel efficiency can vary depending on the vehicle type and design. Factors such as weight, aerodynamics, tire type, transmission, and overall drivetrain configuration play a significant role in determining fuel efficiency. While differential gears are a part of the drivetrain, their influence on fuel efficiency needs to be considered in conjunction with other vehicle characteristics.

In summary, differential gears can affect fuel efficiency in vehicles primarily through their gear ratio, friction and efficiency losses, and traction characteristics. While the impact on fuel efficiency is generally modest, optimizing the gear ratio and minimizing frictional losses can contribute to improved fuel economy. Additionally, the traction benefits provided by limited-slip differentials or advanced traction control systems can indirectly enhance fuel efficiency by reducing power wastage in wheel slip situations.

How do differential gears contribute to handling and stability in vehicles?

Differential gears play a significant role in enhancing the handling and stability of vehicles. Here’s a detailed explanation:

Differential gears contribute to handling and stability in vehicles in several ways:

1. Independent Wheel Rotation:

One of the primary contributions of differential gears is allowing the wheels to rotate independently. During turns, the outer wheel needs to travel a greater distance than the inner wheel. The differential gear enables this speed differentiation, ensuring that each wheel can rotate at a different speed while still receiving power from the engine. This independent wheel rotation enables smoother and more controlled handling during turns.

2. Balanced Power Distribution:

The differential gear distributes torque between the wheels, allowing them to receive power and propel the vehicle forward. By balancing the power distribution, the differential helps maintain stability during acceleration and deceleration. It ensures that both wheels receive an appropriate amount of power, preventing excessive wheel spin or traction loss, which can affect the vehicle’s stability.

3. Enhanced Traction:

Effective traction is crucial for handling and stability. Differential gears play a key role in optimizing traction. In situations where one wheel encounters reduced traction, such as on slippery surfaces or during cornering, the differential allows the wheel with better traction to receive more power. This torque distribution helps maximize the vehicle’s ability to maintain forward motion and improves overall stability by minimizing wheel slip.

4. Improved Steering Response:

The differential gear contributes to improved steering response, which is essential for handling and stability. By allowing the wheels to rotate independently, the differential enhances the vehicle’s ability to respond to steering inputs. It enables precise and controlled turning, allowing the driver to navigate corners and curves with better accuracy and confidence.

5. Balanced Weight Distribution:

Proper weight distribution is critical for optimal handling and stability. The differential gear helps maintain balanced weight distribution among the wheels. During turns, the weight of the vehicle shifts towards the outside wheels. The differential allows the outer wheel to rotate faster, accommodating this weight transfer and promoting stability. By ensuring balanced weight distribution, the differential contributes to predictable and controlled handling.

6. Prevention of Wheel Hop:

Wheel hop, which refers to the rapid up-and-down movement of the wheels during acceleration or on uneven surfaces, can negatively impact stability and handling. The differential gear helps prevent wheel hop by allowing the wheels to rotate at different speeds. This flexibility in wheel rotation reduces the likelihood of wheel hop, improving stability and maintaining better traction on the road.

In summary, differential gears contribute significantly to handling and stability in vehicles. They enable independent wheel rotation, balance power distribution, optimize traction, improve steering response, maintain balanced weight distribution, and prevent wheel hop. By facilitating smooth and controlled handling, the differential gear enhances the overall stability and performance of vehicles.

editor by CX 2023-12-04